- Home

- Companies

- RunDry Evaporators

- Products

- RunDry - Model RD-G10 (10GPH) - ...

RunDry - Model RD-G10 (10GPH) -Gas-Powered Wastewater Evaporator Unit

RunDry’s RD-G10, 10gph RunDry Evaporators are a very efficient alternative for disposing of the wastewater from your industrial facility.This unit can be operate for about $0.08USD/gallon or $0.02USD/liter, this is a significant saving if you are paying for a waste hauler to take your wastewater away!

The RD-G10 RunDry Evaporators are super for medium size machine shops or food processors that scrub their floors often. Many customers that are looking at our 7gph electric units will actually buy this unit for the cheaper operating cost and for future expansion. Click here for many more applications.

The large evaporation tank holds 85 gallons or 321 liters but even that is not limiting if you get the very popular option to add the autofill feature. These RunDry Evaporators run most efficiently when they are equipped with this autofill option. You accumulate your wastewater in a surge tank and the autofill just keeps topping off the RunDry Evaporator™. It’s your choice if you wish to operate the units in the batch mode or the autofill mode.

The RD-G10 RunDry Evaporators™ has an evaporation rate of 10 gallons per hour or 40 liters per hour. This is based on clean water at ambient temperature. Please note that clean water evaporates at 212°F or 100°C, however as you introduce waste products to your water it can alter the boiling point. It is simple to adjust the operating temperature to accommodate your wastewater, but you should be aware that it may have a slight impact on your evaporation rate.

The competition can only evaporate approximately 90% of your wastewater. This leaves you with 10% to drum off and pay a waste-hauler to take away and dispose of properly.

Operation > Savings:

- 8 hrs/day > SAVE $3,120/YR*

- 16 hrs/day > SAVE $6,240/YR*

- 24 hrs/day > SAVE $9,360/YR*

* Based on operating 5 days/week and a national average hauling cost of $1.50/gal.

The 10gph (38 L/H) RunDry Evaporators™ are super for medium size machine shops or food processors that scrub their floors often. Many customers that are looking at our 7gph electric units will actually buy this unit for the cheaper operating cost and for future expansion.

What Makes RunDry Unique?

Our competitor’s evaporators can only evaporate about 90% of the wastewater. The remaining 10% is accumulated in drums or a tank and they often pay $2/gallon to have it hauled away.

A RunDry Evaporator™ can boil off ALL THE WATER and only leave the contaminants behind.

We have actually run our units dry for hours without damage. If a competitor’s evaporator ran dry, it would do major damage and result in a significant repair bill.

Since our unit can RunDry™, we actually encourage the customer to do so because it will eliminate the need to haul away a concentrated wastewater. If solids are present in the wastewater, the solids will drop out as a sludge during the evaporations process. If there is a lot of oil in the wastewater, the RunDry process will generate a residue of oil or an oil and sludge combination.

- Model No: RD-G10

- Evaporation Rate: 10-11 GPH (38 to 42 L/hr)

- Heat Source: Gas or LPG

- Power Consumption: 150,000 BTU

- Electrical Draw: 120V, 20A

- Dimensions (l x w x h): 53″ x 38″ x 44″ (135cm x 97cm x 112cm)

- Weight: 1500 lbs. (680 KG)

- Heater Controls: Thermostat

- Steam Exhaust Fan: Draft Induction, 70CFM

- Exhaust Duct Size: 8″ Dia.

- Tank Capacity: 85 gal. (321 L)

- Construction: Stainless Steel

- Heating Chamber: Insulated

- Auto-fill pump and controls

- Chloride Resistant Alloy

- Lift-out Sludge Tray

- RunDry intentionally for maximum waste disposal

- Rapid Return On Investment (ROI), click for more on savings

- Minimal operator interface

- Multiply layers of safety features

- No Drain Line Needed

- Super thick high-temperature insulation makes the sides and top edge cool to the touch

Benefits of a RunDry Evaporator

Numerous companies pay for a waste hauler to take their dirty water away. If these companies would switch over to using RunDry Evaporators™ they would realize these benefits:

Reduce Cost:

It typically cost $1.00 to $2.00 to have wastewater hauled away. RunDry evaporator can save companies a significant amount of their operating cost because they can evaporate waste for $0.08 – $0.25. Many companies have ROI’s of 1 year or less.

Elimination of Storage:

If a waste hauler is used, the wastewater must be accumulated in a storage tank or drums until there is sufficient volume to warrant the trip for the waste hauler. This takes up valuable floor space in the facility. There is also a potential for spills or leaks. RunDry Evaporators™ eliminate all of this!

Reduced Liability:

When a company generates wastewater they are liable for this wastewater from cradle to grave. Therefore, if the waste hauler’s truck leaves your facility and has an accident that causes the wastewater to spill on the road, the company that generated that wastewater will have to pay for the clean up. A RunDry Evaporator™ eliminates this liability.

- Metalworking

- Metal Finishing

- Transportation

- Scrap Metal Recycling

- Printing

- Ultra-filter

- Micro-filtration

- Reverse Osmosis

- Ion exchange

- Chemical Vat Cleaning

- Gas-Line Waters

- Ethylene Glycol

- Propylene Glycol

- Nuclear Waste Wash Water

- Pharmaceuticals

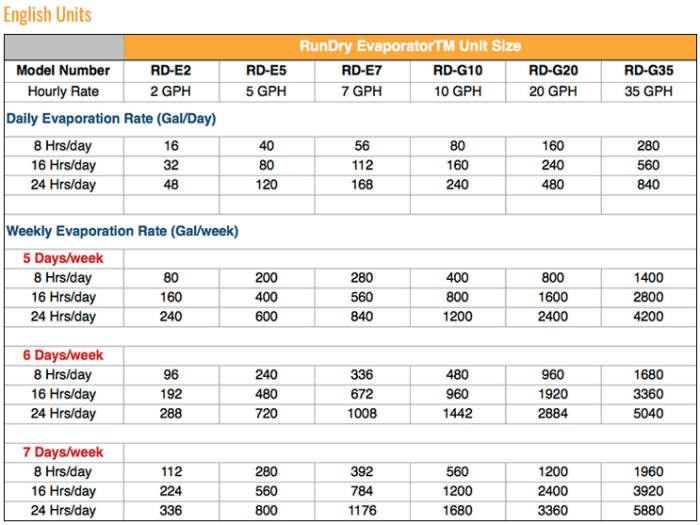

If you are wondering what size unit will meet your needs, this chart will help you make a selection. Here are the things that you will need to know to use this chart:

- How much wastewater does your facility generate in a day or a week?

- How many hours per day are personnel at your facility: 8, 16, or 24?

- How many days per week does you facility operate, 5,6, or 7?

- Does your management plan to have any future expansion, that will cause any of the answers to the first three questions change in the future?

Armed with the answers to these questions, look at the chart ands what size units will meet your needs. All these numbers are based on evaporating clean water. The amount of contamination in your water may impact your evaporation rate, to get a better evaluation on that, take advantage of our free bench test.

You also need to account for some time to run the unit to the point of being dry and cleaning it out. The frequency of this step is a function of how much contamination is in your wastewater. If you would like some help with sizing your evaporator, let us put our experience to work for you and simply complete the Request for Quote!

Our competitors often have a burner tube in their wastewater tank which makes it very difficult to clean out the oil or sludge that is below it. Our wastewater tank is clear with no obstructions, making it very easy to clean. In some cases where there is only oil remaining after evaporating the wastewater, it can be pumped out to a waste oil tank and sold to a used oil reclaimer.

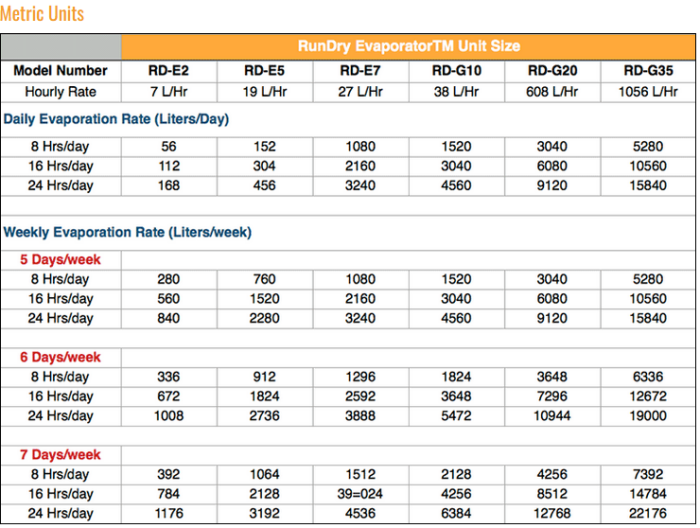

If your wastewater evaporates down to a dry solid or a sludge, we have an option that makes it even easier to clean the unit out – it is a sludge liftoff tray. This stainless tray is placed in the bottom of the evaporator before you start to fill it with the wastewater. Then during the RunDry™ evaporation process, the solids and sludge will settle to the bottom of the wastewater tank and land in the tray. Once your evaporation processing period is finished and the tank has RunDry™, the sludge tray can be lifted out of the evaporator and the sludge can be scraped off into a dumpster.

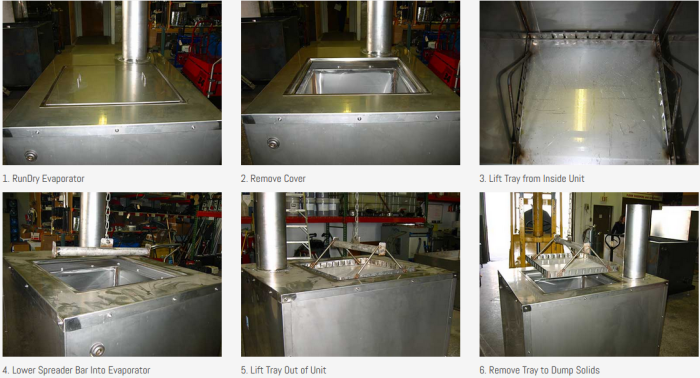

This graph shows the annual cost savings for a company that operates a RunDry Evaporator™ at least 2 shifts per day vs. paying a waste hauler the national average of $1.50 per gallon for disposal of wastewater.

Unit Size: Savings

- 2GPH: $9,173

- 5GPH: $22,932

- 7GPH: $32,104

- 10GPH: $51,685

- 20GPH: $103,370

- 35GPH: $180,899

Wastewater evaporators have two areas where the selection of construction materials can play a big role in the effective life of the unit: the exterior housing and the interior water tank.

The Exterior Housing

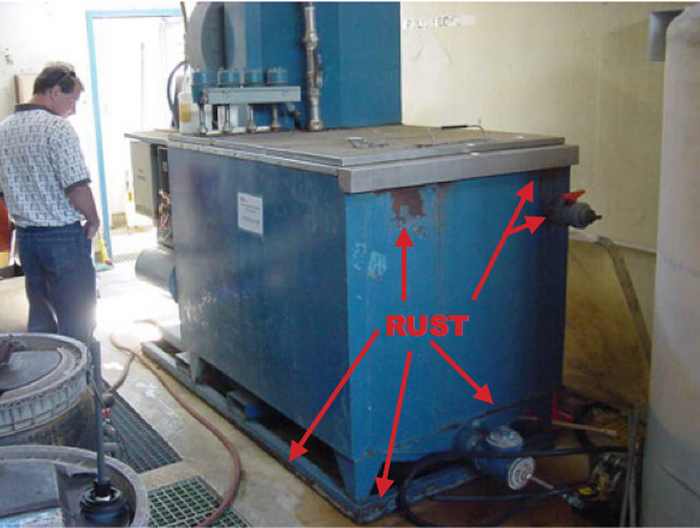

Many of our competitors offer their wastewater evaporators with painted carbon steel as the exterior housings. They do this because it allows them to lower their initial price in an effort to get your business. The problem is that wastewater evaporators are a wet environment and the paint job can get scratched during use. The combination of these two things can result in rust forming on the housing as can be seen in this picture of a competitor’s two year old wastewater evaporator.

RunDry Evaporators have taken the high road and use 304 stainless steel for our exterior housing. This may result in our units having a higher initial cost, however a RunDry Evaporator will stay in service much longer then our competitors. Our life time cost is much lower and our unit look great thought their life time which can be seen in the 2 year old RunDry Evaporator seen in this picture.

The Interior Water Tank

Many of our competitors offer their water tanks in carbon steel and as a result they rust out and have a short life. RunDry Evaporators again went the quality route and made our standard 316L stainless steel. We even offer special alloys for high chloride applications.