- Home

- Companies

- GDS Technologies Ltd.

- Products

- GDS - Model COMBI 80 - ...

GDS - Model COMBI 80 -Direct/Addressable Gas Monitoring System

The Combi has been designed to operate in the full range of environments from commercial premises through to heavy industrial applications which may require hazardous area sensing. Typical monitor locations are - public buildings, car parks, tunnels, breweries, boiler plant rooms, water treatment works, H&V control, manufacturing, process plants, horticulture, hotels, offices.

Combi has been designed to operate in the full range of environments from commercial premises through to heavy industrial applications which may require hazardous area sensing.

Typical monitor locations are - public buildings, car parks, tunnels, breweries, boiler plant rooms, water treatment works, H&V control, manufacturing, process plants, horticulture, hotels, offices.

Each gas sensor continuously monitors the atmosphere, reporting any hazardous conditions to the control unit, for display by the alpha numeric screen indicating the reporting sensor, gas type, concentration and alarm status. Alarm levels that are exceeded will automatically activate a variety of signal outputs including analogue/digital data and user selectable relays.

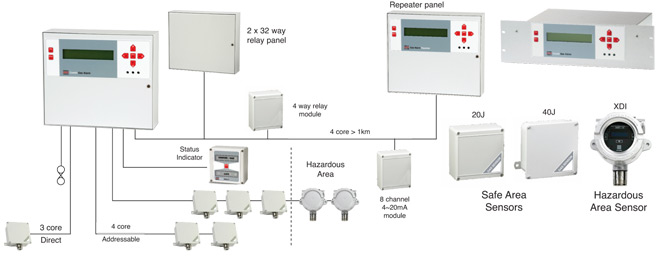

The Combi system operates on a 4-core (addressable) or 2/3 core (direct) cable network and has the capacity to monitor up to 64 addressable and 16 direct sensors of various gas types. Larger systems offering unlimited sensors can be achieved using multiple combi units housed in a 19” rack based system or a single network system. The Combi is supplied ready to use with pre-calibrated gas sensors and provides for additional sensors that can be easily added to any point of the network.

Optional software (Combi Soft) allows full data logging facilities with system management providing real time views showing sensor locations, alarms status and actual gas values.

Sensor points

- 1-64 addressable – CANbus – and/or

- 16 direct 4~20mA

Measurements

- Combustible Gas - L.E.L., % vol

- Toxic Gas - ppm, % vol

- Oxygen - % vol - Depletion/Enrichment

- Refrigerant - ppm

- Any 4~20mA transmitter

Indicators - control unit concentration

- Dot matrix LCD 4 line 40 character - indicating sensor location, gas type, (rising or falling alarms), alarm status, system fault, sensor line fault, sensor fault, inhibit, real time clock, event memory

- Red LED - global alarm, Amber LED - global fault,

- Amber LED-inhibit

Outputs

- 8 user selectable zone/voting – with NE/ND option and delay to de-energise

- Relay contacts - 2 D.P.C.O / 6 S.P.C.O. rated @ 5A-230v AC

- Factory set 1 common low alarm D.P.C.O or group 1

- 1 common high alarm D.P.C.O or group 2

- 1 common overange S.P.C.O or group 3

- 1 common fault alarm S.P.C.O or group 4

- 4 user selectable S.P.C.O groups 5 to 8

- General alarm relay - resetable S.P.C.O. for sounders etc.

Optional

- 2 x 32 relays - first 16 programmable with pattern/event with NE/ND options and delay to de-energise - 48 are single event

Optional - remote addressable 4 way relay unit

- RS232 data log - event log

- Modbus - RS485 x2

- Combi Soft: full data logging /management tool - option.

- Individual sensor logging - intervals 1-60 mins storage readings 2880

- Audible alarm

- Alarm/Fault - permanent mute option

Power

- 230/115v AC or 24v DC ±15%

- Control unit 7.5w quiescent 17w full alarm

- Sensor - 1.25w

- Internal power supply: 20 sensors max. 21+ sensors -

- 11A/24vDC Auxiliary Power Pack required C1541/C1293