- Home

- Companies

- Geoprobe Systems -Kejr, Inc.

- Products

- Geoprobe - Model 8150LS - Sonic Drill ...

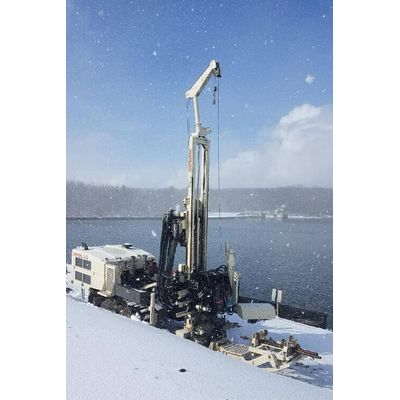

Geoprobe - Model 8150LS -Sonic Drill Rig

Drillers seeking to handle tough site conditions with a single drill rig while preserving the option for sampling and setting wells rely on the 8150LS sonic drilling rig to quickly provide continuous, undisturbed core samples to impressive depths in a wide range of formations. Additional advantages of the sonic drilling rig include:

- Production power from 50,000-pound dynamic force GV5 sonic head, which comes with a 3-year/1,000-hour warranty

- Operator safety from the adjustable swing arm control panel and rod handler

- Expert support via remote diagnostics and a dedicated team of sonic experts

- Pair with SRC30DT rod carrier, rod handler, and indexing rack options to create virtually hands-free operation.

New sonic operators will appreciate the quick learning curve and the comprehensive sonic drill rig training offered by our sonic team – all with years of experience training new operators. Regardless the complexity of the question or the experience of the driller, Geoprobe® sonic drilling rig owners depend on our dedicated team of sonic experts for rapid troubleshooting and training.

Owners praise their Geoprobe® sonic drilling rig for faster, safer production providing better unconsolidated sample data. With many highly productive features and configurations for success, two-man crews use the 8150LS sonic drilling rig to collect high-quality samples and complete multiple applications in a single boring, using 10-foot tooling up to 12-inch diameter. Pair the 8150LS with the SRC30DT rod carrier, rod handler, and indexing rack options to create a virtually hands-free operation.

- SAMPLING: whether in consolidated materials, glacial till, or backfill rubble, quickly complete complex holes to greater depths with the powerful GV5 50K sonic head. Maintain mast and machine position leveraging the dual pivoting winch and head centerline side shift to guide the GV5 head, automatic drop hammer, or coring head to align with the borehole.

- SAFETY: instead of handling large tooling, rely on the rod handler and indexing rack to minimize heavy lifting – reducing fatigue and injury while increasing productivity. Steer clear of spinning tool strings or position comfortably close to align rods with the adjustable swing arm control panel.

- SUPPORT: regardless the complexity of the question or the experience of the driller, depend on a dedicated team of sonic experts for troubleshooting and training. Should something go awry, remote diagnostics mean assistance is a phone call away. Built-in redundancies on key components add another layer of reassurance for finishing the day and addressing an issue at a more convenient time.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have industry-leading sonic drilling rig service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your sonic drilling rig is constructed consistently and tested thoroughly to ensure easier service support.