- Home

- Companies

- Powder Systems Limited (PSL)

- Products

- PSL - GFD® Pilot Nutsche Filter Dryer

PSL - GFD® Pilot Nutsche Filter Dryer

The GFD® Pilot is an Agitated Nutsche Filter Dryer (ANFD) that carries out solid-liquid separation processes at kilolab and pilot scale. It facilitates feasibility and proof of concept activities developed during smaller scale research and development stages. In spite of being a smaller, compact filter dryer, it provides the quality, reliability and efficiency of the full size PSL ANFD filter dryers.PSL’s unique GFD® technology was developed to overcome the well-known production challenges faced by manufacturers when using traditional production methods such as Büchner filtration and oven tray-drying.

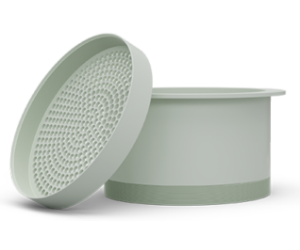

It consists of an agitated vessel designed to work under vacuum and under pressure. The vessel can be made of Borosilicate 3.3 glass, 316L Stainless Steel or Alloy 22 and has a heated jacket for efficient drying. Solid-liquid separation is performed within the unique filtration basket, which can be removed to ease and maximise product recovery.

The GFD®Pilot technology is designed to be the logical scale-up ANFD from the GFD®Lab which is used in laboratory conditions. It assists in evaluation and development of the desired end product prior to scaling up to commercial production.

A filter dryer combines two processing steps within a single piece of equipment. Firstly, solid-liquid separation is carried out, also known as filtration. The second step often consists of washing the product for removing impurities and/or solvent traces. The final step is to dry the collected solids.

In the majority of cases the solid is the product of interest but filter dryer technology can also be used in processes where the filtrate (liquid) is the valuable product. It is also possible to retain both the solid and the filtrate, if required.

- A fully sealed vessel which can be pressurised or put under vacuum.

- A bi-directional agitator within the vessel with a height-adjustable blade to account for variable product cake thicknesses.

- A filtering element at the base of the vessel, usually mesh.

- Temperature controlled zones including heated jackets and in some cases a heated agitator.

The Agitator within Nutsche Filter Dryers provides superior performance over traditional methods such as Buchner Filtration and Tray Dryers by offering the following features.

- Preventing heavy build-up on the filtration screen by keeping the product in motion in order to keep a rapid filtration rate.

- Maintaining efficient pressure filtration by smoothing the top surface of the wet cake.

- Providing homogenous drying throughout the batch by gently mixing (ploughing) powder.

As an early pioneer of containment technology, PSL enhances its filtration and drying solutions with unique high-containment systems.

Many industrial filtration and drying processes require integrated containment technology in order to protect operators from highly toxic compounds and/or to protect sensitive products from the production environment. PSL containment systems can be integrated to allow end-users to complete a large range of process operations such as product sampling and product discharge while protecting the product integrity and maximising product yield.

PSL offer a range of containment solutions for integration with our filter dryers. Selection is based on the containment performance requirement and/or organisational preference for either rigid containment or flexible/disposable solutions.

ANFD are a mainstay in fine chemical and pharmaceutical manufacturing. Find out why with this brief overview of ANFD technology.

Combined Filtration and Drying

The GFD®Pilot is an all-in-one filter dryer designed for use at pilot plant production scale. It complies with Good Laboratory Practices (GLP) and is commonly used for pharmaceutical and fine chemical processing applications. Developers and manufacturers can complete a wide range of processes in a single, standardised system:

- Slurry Filtration (solid-liquid separation)

- Product Washing

- Re-slurry

- Vacuum Drying

- Product Sampling

- Product Discharge

Maximising yield is crucial at pilot scale feasibility stages and/or small-scale production. The GFD®Pilot is designed with this in mind, given the importance of the final product.

Following process completion, the product batch is collected with ease due to the design of the filtration basket which can be removed completely from the GFD® vessel.

The GFD® basket is suitable for multi-product applications as it facilitates quick and easy changeover of filtration meshes with various pore-sizes and materials such as Polypropylene, PTFE, 316LSS and Alloy 22.

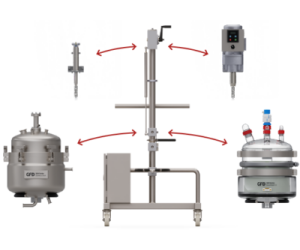

The compact, mobile GFD®Pilot filter dryer provides production flexibility due to its modular design.

As with the GFD®Lab range, the base frame and motor are compatible with all relevant vessel materials (Borosilicate 3.3 Glass, 316L Stainless Steel and Alloy 22) offering a simple, fit-for-purpose solution.

The GFD®Pilot is mounted on a mobile frame to allow integration with various upstream processes.

The frame has been designed as compact as possible to allow integration within fume cupboards and walk-in laminar flow booths.

When scaling up to the operational volumes available with the GFD®Pilot, the use of organic solvents in chemical and pharmaceutical processes often means hazardous area considerations must be taken into account.

To overcome this, PSL offers alternative agitator drives suitable for such environments with appropriate certification, for example ATEX and NFPA.

Additionally, the use of pneumatic motor drives ensures the design is kept compact.

When higher operation pressures are required, metallic versions of the GFD® Pilot are available.

These are designed and manufactured in accordance with the Pressure Directives of the place of installation. PSL can deliver U-Stamp, PED and SELO certification, as required.

As one of the early pioneers of containment technology, PSL developed the unique FilterBox isolator range to accommodate all the types of vessel used with the GFD®Pilot.

By opting for a GFD®FilterBox operators are safe-guarded from the most toxic/potent compounds and the product is protected from production environments.

PSL can also provide integration packages with/for third-party containment providers.

- Typical Product Cake Volume: 0.93 – 5.00L

- Vessel Volume: 10.0L

- Filtration Area: 0.05m2

- Frame Dimensions (H x W x D): 1680 x 784 x 650 mm