- Home

- Companies

- Kerfoot Technologies, Inc. (formerly ...

- Products

- KTI Perozone - Giving Bubble Power a ...

KTI Perozone - Giving Bubble Power a Big Cleanup Boost

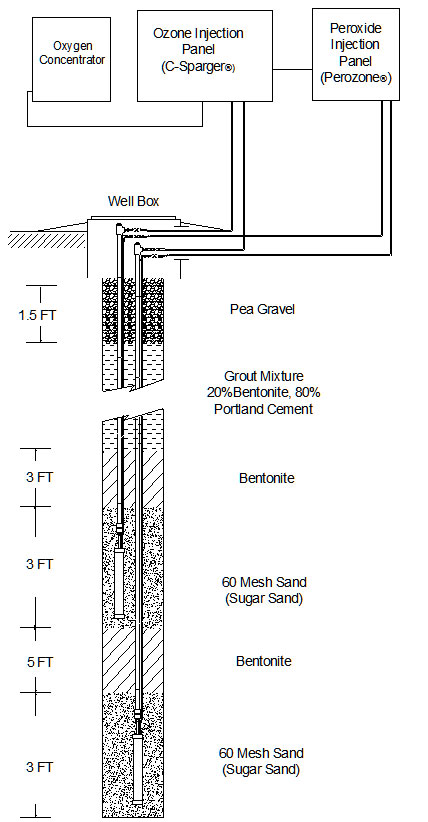

KTI’s Perozone® system creates peroxide-coated microbubbles using our unique injection process to greatly enhance destruction of targeted contaminants. Adding a small liquid injection panel to our C-Sparger® ozone remediation system enables co-injection of peroxide through our Laminar Spargepoints®.

The secret of success is in the creation of the hydroperoxide-coated ozonated microbubbles by our Laminar Spargepoints, followed by the pressure-pulsed injection of these minute bubbles through the Laminar Spargepoints into a wide variety of formation pore spaces ranging from sands to silty clays to low-permeable fractured bedrock.

By using low concentrations of peroxide coupled with low injection rates (mL/min, not gpm), an efficient chemical ratio of the peroxide- coated microbubble of ozonated gas is created. The enormously increased surface area afforded by microbubbles results in significantly more reactions by more contact with the contaminants of concern, inherently rapidly breaking down long-chain hydrocarbons (weathered gas and oil), aromatic ring compounds, halogenated alkenes and alkanes, certain ethers, as well as a host of other contaminants such as PAHs, PCBs, pesticides such as chlordane and heptachlor, and 1,4 dioxane.

From bench-scale to pilot-scale to full-scale operations, KTI is empirically and theoretically the expert in efficient system design and operation, matching system capacity to site needs. Impressive decrease of contaminant mass and concentration in soil and water may be seen in weeks! The end result is a clean site with beneficially increased oxygen remaining after the decomposition process.

- Low capital equipment/operating costs

- Ease of installation and setup

- Requires standard 120VAC household current

- Minimal installation site disturbance

- Variety of systems: wall-mount, modular, trailer

- Ozone/peroxide matched to site requirement (from 0.5-8.0 lbs/day ozone)

- Hydroxyl radical formation dramatically boosts reaction potential

- Pulsed microbubble oxidant injection ensures maximum contaminant contact

- Clean in-situ destruction of contaminants – no hazardous byproducts

- No vapor control necessary Does not form hexavalent chromium

- MODEL 8100 (WALL-MOUNT)

- PEROZONE SPECIFICATIONS

- ¾ or 1 HP (2-5 SCFM) continuous service compressor

- 8-16 gr/hr (0.42-0.84 lbs/day) ozone output

- 0-40 mL/min hydrogen peroxide injection

- Delivery pressure up to 75 psig

- 6-24 sparging zones

- PSA oxygen concentrator

- PLC controlled

- 3/8” – ½” carrier tubing

- Panel dimensions:

- Gas Panel: 43”W x 29.5”H x 12”D

- Liquid Panel: 29.5”W x 29.5H x 12”D

- Oxygen Panel: 18”W x 27”H x 10”D