Glen Mills Inc

- Home

- Companies

- Glen Mills Inc

- Products

- Glen-Mills - Model GM -1200 - Hammer ...

Glen-Mills - Model GM -1200 -Hammer Mill

FromGlen Mills Inc

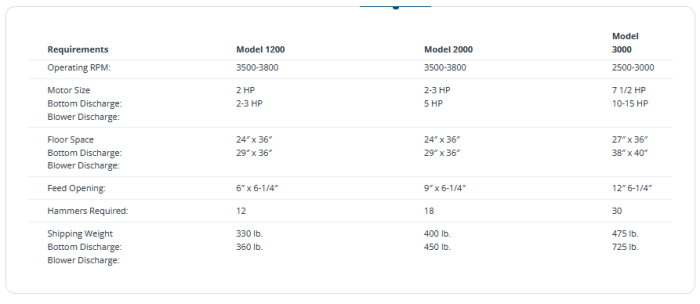

Uncomplicated design with range of uses and installations. Top chamber tilts open for inspection and maintenance. Heavy ribbed cast iron breaker plate aids in the grinding and milling process. Rotor shaft 1-3/16″ dia. steel with flange mounted ball bearings and grease fittings Hardened steel hammers, free-swinging, four rows installed in staggered arrangement Hammers are reversible for maximum wear.

Most popular related searches

hammer mill

grinding hammer mill

grinding mill

dry grinding

blower

mounted bearing

blower unit

discharge regulations

track screen

maintenance inspection

- Milling chamber has radius tracks for sizing screen

- The Bottom Discharge feature permits easy installation over a pit, hopper or similar and is completely open for full and quick through-put

- The Blower Discharge Mill features a fan which helps in fast grinding by pulling material into the rotating hammers and through the screen

- The Blower fan moves material to another area or upper level to over 20 ft. elevation

- The Blower Discharge unit is well suited for dry, light weight material such as most grains, feathers, foam plastic, feed, dry bedding and much more

- All Hammer Mills are made of durable cast iron and formed steel

- All are finished in standard red enamel

- Stock screen included

- Standard Feed Table

- Base Frame with motor mount (formed & welded steel)

- Electric Motor for *230/460V-3 ph-1750 RPM operation eOn/off control with O.L. protection & enclosure

- 25 ft. power cord with plug

- AII pulleys with v-belt drive for proper speed

- Safety Limit Switch (to stop motor if mill is opened) eSafety Belt Guard with motor cover

- PVC Discharge Skirt (for Bottom Discharge units)

- AII ready for operation