Gorbel Inc.

- Home

- Companies

- Gorbel Inc.

- Products

- Gorbel - Cleveland Tramrail Underhung ...

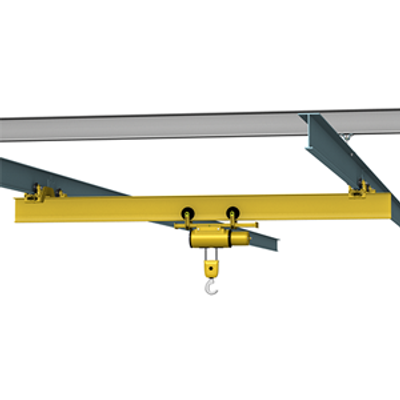

Gorbel - Cleveland Tramrail Underhung System

FromGorbel Inc.

Our patented track underhung crane systems have an impressive track record of reliable, long-lasting service in high-duty-cycle applications, loading docks, parts assembly, equipment maintenance and truck service centers. Cleveland Tramrail®’s underhung crane systems can be used to efficiently move material through an entire production facility. With capacities from 5 to 40 ton, our underhung systems are superior to I-Beams in strength, durability, and consistency while also offering extended track life. Our Cleveland Tramrail® Underhung Systems are easily changeable and expandable, making them cost effective for your facility.

Most popular related searches

- Capacity: 2 to 40 tons

- Span: Up to 60`

- Height: N/A

- Coverage Area Type: Square or Rectangular

- Coverage Area: 60` W x Unlimited Length

- Motorization: Yes

Here are some key features of our Cleveland Tramrail Underhung Systems:

- Straight rails result in easy, predictable, cost effective installations

- Efficient spanning capabilities eliminates costly additional supporting structures

- Raised tread tarca track provides durability and superior safety

- Flexible suspensions provide for longer life and less maintenance

- Superior to I-Beams in strength, durability, and consistency

- Extended track life compared to I-Beam Systems

- System expansions are easy and cost effective

- Straight rails result in easy, predictable, cost effective installations

- Efficient spanning capabilities eliminates costly additional supporting structures

- Raised tread tarca track provides durabillity and superior safety

- Flexible suspensions provides for longer life and less maintenance

Options:

- Aluminum enclosed track bridges

- Double girder

- Multiple runways

- Low headroom options

Accessories (Add-Ons):

- Interlocks/Transfers

- Drives

- Curves

- Switches

- Safepowrbar electrification

- Hot metal

- Necropsy Lab

- High duty cycle applications

- Parts Assembly

- Warehouse loading docks

- Process Equipment Maintenance

- Truck Service Centers