- Home

- Companies

- Calgon Carbon Corporation

- Products

- Calgon Carbon Filtrasorb - Model 820 - ...

Calgon Carbon Filtrasorb - Model 820 -Granular Activated Carbon

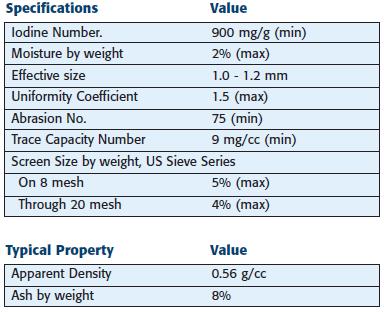

FILTRASORB 820 is a granular activated carbon developed by Calgon Carbon Corporation for the removal of taste and odor compounds, disinfection by-product precursors, and other dissolved organic compounds from potable water. This activated carbon is manufactured from selected grades of bituminous coal to produce a high-activity, durable, granular product capable of withstanding the abrasion associated with repeated backwashing, air scouring, and hydraulic transport. Activation is carefully controlled to produce an equal blend of both low energy pores as measured by iodine number and high energy pores as measured by trace capacity number for effective adsorption of a broad range of high and low molecular weight organic contaminants. The product is also designed to comply with all the applicable provisions of the AWWA Standard for Granular Activated Carbon edition B604-05, the stringent extractable metals requirements of ANSI/NSF Standard 61, and Food Chemicals Codex.

- Calgon Carbon`s reagglomerated coal-based granular activated carbons have several properties which provide superior performance in a wide range of applications.

- Produced from a pulverized blend of high quality bituminous coals resulting in a consistent, high quality product.

- The activated carbon granules are uniformly activated through the whole granule, not just the outside. This results in excellent adsorption properties and constant adsorption kinetics in a wide range of applications.

- The reagglomerated structure ensures proper wetting while also eliminating floating material.

- High mechanical strength relative to other raw materials, thereby reducing the generation of fines during backwashing and hydraulic transport.

- Carbon bed segregation is retained after repeated backwashing, ensuring the adsorption profile remains unchanged and therefore maximizing the bed life.

- Reagglomerated with a high abrasion resistance, which provides excellent reactivation performance.

- High density carbon resulting in a greater adsorption capacity per unit volume.

- Provides higher hardness relative to other raw materials reducing the generation of fines and product losses during backwashing.

- Pore structure provides an equal blend of low and high energy pores for effective removal of a broad range of high and low molecular weight organic compounds.

- Wets readily and does not float, thus minimizing loss during backwash operations.

- Creates optimal transport paths for faster adsorption.

FILTRASORB 820 is used primarily to treat surface water sources for the production of drinking water. This carbon is a coarser mesh media and is generally used in deep bed filters where pressure drop may be a concern. FILTRASORB 820 functions as a dual purpose media providing both filtration and adsorption.

Design Considerations

As a replacement for existing filter media, the conversion to FILTRASORB 820 activated carbon imposes no major changes to a plant`s normal filtration operations. If more contact time is required, the height of the backwash troughs can be increased. Calgon Carbon Corporation can also provide complete modular adsorption systems as an add-on treatment stage if required.

Packaging

- 55 lb. (25 kg) poly bag

- 1,000 lb. (454 kg) super sack

- Bulk trucks

- Safety Message

Wet activated carbon preferentially removes oxygen from air. In closed or partially closed containers and vessels, oxygen depletion may reach hazardous levels. If workers are to enter a vessel containing carbon, appropriate sampling and work procedures for potentially low oxygen spaces should be followed including all applicable Federal and State requirements.