- Home

- Companies

- Calgon Carbon Corporation

- Products

- Calgon Carbon - Model CR5000 - Granular ...

Calgon Carbon - Model CR5000 -Granular Activated Carbon Adsorber Vessel

The CR5000 carbon adsorber is a pressure vessel designed to treat water or other liquids using granular activated carbon (GAC). The CR adsorber contains all of the operating elements required for utilization of granular activated carbon in water treatment, including a corrosion resistant underdrain for effective treated water collection and a corrosion resistant inner coating to protect the carbon steel vessel.

The CR5000 adsorber has capacity for 5,000 pounds of GAC and treats flows to 250 gpm. The initial GAC fill can be provided separately for filling the adsorbers at the site, or shipped dry in the adsorber vessel.

The CR adsorber can be provided with any of Calgon Carbon`s wide variety of liquid phase granular activated carbon products that can be specifically selected for a specific water or liquid treatment application. Most commonly used are Filtrasorb grade virgin activated carbon for higher purity water or optimal carbon usage for low levels of organic contamination, or DSR series quality controlled reactivated grade carbon for a more economical carbon product or for wastewater treatment.

The CR5000 carbon adsorber offers several important features that make it an effective value driven option for many water treatment applications:

- Carbon steel pressure vessel at a rating of 50 psig at 100° F

- Interior coated with a corrosion resistant epoxy coating

- Exterior painted with a durable epoxy finish

- Top 14X18 access port for activated carbon media fill and removal

- Underdrain consisting of PVC pipe laterals with PPL water collection septa for even water collection and maximum activated carbon utilization.

- High flowrate design consisting of large process connections and high count of water collection septa to minimize pressure drop at higher flowrates.

- Inlet flow defector for introduction of influent water above the carbon bed.

- Option of spent carbon removal either by pressurized slurry discharge or vacuum removal.

- Top lifting lugs and bottom forklift guides for portability and ease of installation.

- Flexibility in handing varying flows and on-off conditions by use of downflow fixed bed adsorber design.

- OPTION of combining two CR adsorbers into a complete two stage design by incorporating convenient piping system.

- Adsorber vessel : Sturdy carbon steel pressure vessel with dished head

- Pressure: Designed for 50 psig maximum operating pressure; shop hydrotested in excess of recommended pressure

- Temperature: Recommended 100°F maximum

- Internal coating: Epoxy

- External coating: Epoxy

- Inlet: 150# ANSI flange

- Inlet distributor: PVC inlet flow deflector

- Outlet: 150# ANSI flange

- Outlet collector: PVC pipe laterals with PPL slotted water collection septa

- Vessel Drain/ Carbon outlet: Stainless steel outlet pipe with bronze ball valve and NPT connection

- Access Port: 14" X 18" access port with EPDM gasket

- Dimensions : Refer to Model Chart

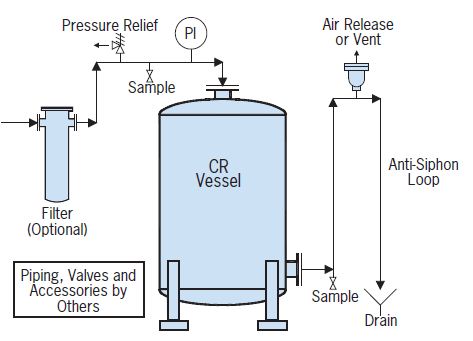

PCR adsorber is shipped either empty or with dry activated carbon installed in the vessel. The CR adsorber can be moved using a fork lift or lifted by a crane using the lifting lugs. The adsorber should be positioned on a flat level surface capable of supporting the operating weight and piped as recommended in the installation illustration. The vessel can be secured to a foundation by using the forklift guides as base plates.

The CR adsorber discharge piping should include an elevated piping loop to ensure that the adsorber remains flooded with water at all times. In addition to the piping loop, a drain connection is recommended on the discharge piping to allow for drainage of the adsorber prior to disconnection or during a temporary shutdown. A filter should be installed prior to the adsorber if the water to be treated contains substantial amounts of suspended solids. A simple cartridge of screen filter helps prevent pressure buildup in the carbon bed. A pressure relief device should be installed in a line open to the adsorber if the system can potentially be subject to pressures beyond the design point.

The carbon must be wetted and deaerated prior to use. This procedure displaces air from the internal structure of the carbon granule, assuring that the liquid to be treated is in contact with the carbon surface.

If the adsorber was provided empty, then the adsorber should be first filled with the dry carbon, using either bags or 1000 lb supersacks using the top access port. Prior to opening the access port, the inlet and outlet to the adsorber should be securely closed. In order to prevent damage to the PVC underdrain system, a ``water cushion" is to be added to the adsorber such that the water covers the underdrain system by approximately 1-2 feet. Once the fresh carbon is installed, the access port securely closed, and the inlet and outlet connections are reestablished, the carbon can be wetted and deaerated.

Prior to operation, each adsorber must be filled with clean water; the water should be introduced into the bottom effluent connection. The adsorber should sit for approximately 48 hours to allow most of the carbon`s internal surface to become wetted as shown on the wetting curve.

After wetting, the carbon bed can be deaerated by draining the adsorber from the effluent line and then refilling the adsorber upflow with clean water. This procedure will eliminate any air pockets which may have formed between the carbon granules. The CR adsorber is now ready for operation.

The CR adsorber should be full of clean water or liquid before treatment begins. Flow rate to the unit should be determined based on required contact time between the liquid and the carbon media. In groundwater treatment applications, the recommended contact time, calculated on an ``empty bed basis", is typically 8-10 minutes. Consult your Calgon Carbon Corporation Technical Sales Representative for advice about proper contact time for your application.

CR adsorbers can be manifolded in parallel operation for higher flow rates. For series operation, two CR adsorbers can be piped together sequentially, as normal pressure drop will not exceed the recommended operating pressure. Calgon Carbon offers a complete two stage system using CR adsorbers if two stage operation is preferred.

Operation is started up by initiating water flow to the unit by first opening the inlet valve and then the outlet valve to the adsorber. Opening the inlet valve first prevents any draining or siphoning of water from the adsorber, which needs to remain full of water at all times during operation. This flooded condition is maintained by either the anti-siphon loop shown in the installation drawing or by maintaining backpressure on the adsorber.

The CR adsorbers have minimal space for bed expansion with the design amount of carbon installed, but can be moderately backflushed to eliminate some filtered solids or entrained air by introducing clean water or process liquid at approximately 2-3 gpm/sf to the effluent connection and taking backflush water from the influent connection, and directing this water to a drain suitable for receiving contaminated water with suspended solids and carbon particles.