- Home

- Companies

- WaWaTech – Wastewater Technology Sp. z ...

- Products

- WaWaTech - Model BIOCOS - Granular ...

WaWaTech - Model BIOCOS -Granular Bioreactor for Wastewater Treatment

The BIOCOS® Granular Bioreactor is an innovative solution designed for advanced wastewater treatment. This system combines the benefits of suspended growth and granulating sludge technologies, offering superior sludge settling characteristics through biological and physical selection mechanisms. Unlike traditional systems, BIOCOS® operates efficiently with continuous feeding and discharge at a constant water level. This cyclic activated sludge process includes aeration, mixing, sedimentation, and discharge phases, using pressurized air to eliminate the need for electro-mechanical equipment. Developed initially at the University of Innsbruck, the technology has been refined in Germany and Austria, resulting in hundreds of installations worldwide. The process enhances the biological removal of carbon, nitrogen, and phosphorus, making it a highly efficient choice for biological nutrient removal. Additionally, it boasts a low energy footprint and robust operation, embodying the hybrid nature that its name – BIOlogical COmbined System – suggests.In our portfolio we have several technologies for aerobic biological treatment. Where other systems are based on suspended growth (activated sludge), attached growth (MBBR) or granulating sludge (Demon®) systems, this BIOCOS® has benefits of both suspended and ‘granulating’ sludge. The main improvement is the selection mechanisms to get the ‘granulating’ sludge, a sludge with much better settling characteristics. Basically, it’s about biological selection mechanisms. Secondly, it’s in combination with inDENSE™ about physical selection as well. BIOCOS® is an efficient solution for biological removal of carbon, nitrogen and phosphorus. Making it a very interesting biological nutrient removal (BNR) solution as well.

BIOCOS® is the proven innovation for ‘granulating’ aerobic activated sludge systems. Energy efficient! Simple! Robust!

Its name originates from it’s representation of a hybrid technology: BIOlogical COmbined System, in short BIOCOS®.

BIOCOS® is one of the most innovative and proven solutions for wastewater treatment. The technology was developed at the University of Innsbruck, and has undergone further development in Germany and Austria. Nowadays, hundreds of these systems are operational worldwide.

BIOCOS® is a cyclic activated sludge system with an aeration tank hydraulically connected to two alternating sludge recycling and settling tanks. The effluent valve of one of the settling compartments is open allowing the feed flow to the aeration tank to push out the supernatant water from the corresponding settler. No RAS pump-station or any electro-mechanical equipment for mixing or recycling is required – all phases of the operation cycle are exclusively driven by pressurized air from the same blower-source saving a lot of effort in operation and maintenance.

Sludge Recycle (RAS) Phase.

Recycling of the thickened bottom layer of the settled sludge blanket from the ALT-tank to the selector zone of the AIR-reactor is provided by means of an air-lift. The transfer of the compressed sludge layer allows for a 50% higher MLSS in the aeration tank vs the settler compartments.

Mixing (MIX) Phase.

The ALT-tanks are mixed by a roll current induced by coarse bubble aeration for a few minutes. High mixing intensity homogenizes and re-aerates the anoxic sludge blanket.

Sedimentation (SED) Phase.

Settling sludge blanket creates formation of a floc-filter for fine particle removal and development of a dense bottom sludge layer.

Discharge (DIS) Phase.

Intermittent aeration in the AIR-tank for nitrogen removal and continuous discharge of supernatant water from ALT-tank (no water level variation).

Process cycle overview.

Typical for above cycles.

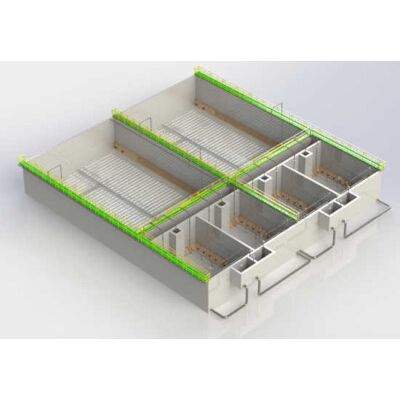

Plan view.

Typical for above visualised system.

- Enhanced Bio-P activity – Biomass minimizes demand for chemical phosphorus precipitation.

- Small tankage – Reliably improved settling performance due to densified biomass significantly reduces overall system volume.

- Post-denite capability – Typically up to 50% of the nitrogen removal occurs in the sludge blanket of the settling compartments and therefore this post-denitrification approach is highly suitable for low BOD5/N ratios in the feed.

- Low fine particles – Sequenced settling of the sludge blanket forms a floc-filter which reliably removes fines, producing an effluent low in suspended solids suitable for water reuse.

- Simple O & M – No mechanical equipment within the aeration tank and the settlers while blower air is utilized for RAS-recycle and mixing resulting in low maintenance requirements.

- Low space demand – Common-wall construction allows for a compact footprint with the reduced need for external piping runs and recycle pump station.

- Less energy demand – Substantial savings due to lack of mechanical devices while the addition of a good control system reduces the aeration demand for nutrient removal.

- Capital investment savings – Lower investment costs due to lack of mechanical equipment (only blowers and in-tank piping compared to scrapers, mixers, recycle-pumps) and common wall construction between the AIR and ALT Reactors.

- Innovative but proven technology – more than 100 reference plants.