THM Recycling Solutions GmbH

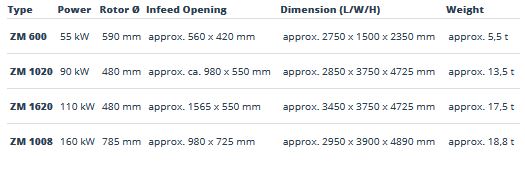

THM - Model ZM -Granulator

The extremly robust ZM Granulator were develop for the size reduction of metals but doesalso perform very well when size reducing other materials such as cable waste, plastics and other materials. Nomatter which type of materiasl is fed into the ZM Granulator - metal, recyclable waste or substitutes fuels - the ZM granulator performs brilliantly. All components are designed for a maximum durability. The rotor of the ZM Granulator is manufactured out of rolled and forged steel and made for a demanding long term use even in the field of scrap metal recycling.

Most popular related searches

scrap metal recycling

granulator

metal recycling

industrial waste

size reduction

plastic waste

pre-shredding

tire shredding

cable scrap

scrap metal

Extreme robust

The ZM Granulator from THM is made for a large thrughput capacity. The field of application is exceptional large:

- Domestic and industrial waste

- Electro- and electronic wastel

- Pre-shredded tires

- Aluminium shavings from turning and milling

- Die cast parts and stell profiles

- Cable scrap

- Oil filters

- Steel and plastic barrels

- Plastics

- Paper

- etc.

ZM Granulator: all benefits at aglance

- High througput capacity up to 20 t/hr

- Working width from 300 mm to 1.600 mm (2000 mm) and drive power from 7,5 kW bis 160 kW

- Constant cutting quality because of re-adjustable knives

- High performance reserve even when cutting massive metal parts

ZM Granulator: processed material fractions

- Fraction size from 10 - 100 mm

- Aluminium

- Plastics

- Textiles

- Cabels

- etc.