- Home

- Companies

- Ningxia Yongruida Carbon Co., Ltd.

- Products

- Yongruida - Graphite Carburizer

Yongruida - Graphite Carburizer

Our company is specialized in producing and processing, low nitrogen carburant, graphite electrode, graphite products, the calcined petroleum coke is 3000 DEG C high temperature graphitization structure, reduce harmful components of sulfur, nitrogen and phosphorus, ash, etc. With a high degree of graphitization, than the major absorption rate is high and fast, and promote the process of breeding and the ball, effectively improve iron graphite, reduce iron cementite, with today is market crushed graphite carphite coke carbon additives and low price, the use effect rather, has been widely recognized by the market.

- High fixed carbon, high absorption rate, low sulfur and nitrogen, and the absorption rate faster than similar graphitization carburant, and absorption of furnace wall, completely absorbed no residue, the price is lower than the similar pieces of graphite electrode low sulfur carbon agent, the highest price.

- High absorption rate, according to the use of the method to achieve the highest absorption rate can reach more than 90%.

- Fast absorption rate, fastre than similar graphitized carbon absorption, adsorption of furnace wall, and no residual, furnace carbon absorption speed advantage is more obvious.

- The nitrigen content, the lowest was less than 100ppm in the same graphitization of low nitroen carburant in the price advantage.

The main raw material for synthetic graphite is powdered smoldering petroleum coke. The asphalt is used as a binder and a small amount of other auxiliary materials are added. After the various raw materials are combined, they are compression molded. It is then treated in a non-oxidizing atmosphere at 2500-3000 ° C for graphitization.

The synthetic graphite products are expensive. Most of them used in the foundry industry is chips, scrap electrodes and graphite blocks when manufacturing graphite electrodes. These materials can be recycled. And in the production process to play a role in heating up and increasing carbon. At the same time, it can greatly reduce production costs.

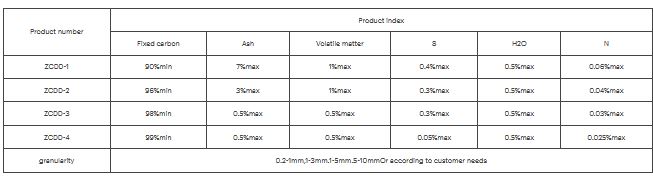

Analysis Method:Analysis of the prodcut according to requirements of GB /T7702-2008. Packing :25KG wear ,woven outer layer,the inner layer of plastic film,or according to customer needs separately.