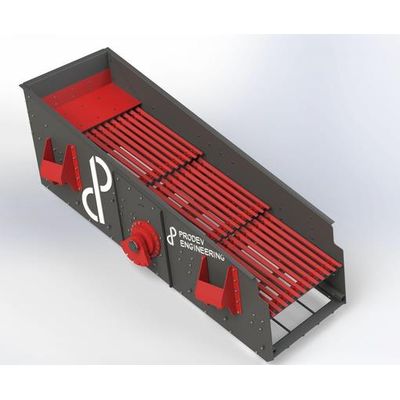

Proscreen - Model G1230 -Grizzly Screen

There are grates made of cast or sheet metal as screen panel on the top deck where material is fed. The pieces passing through the distance between these grates pass to the lower screen panel. In the lower decks, perforated sheet metal or steel mesh screen is used as a screen panel. This type of screen is generally used to quickly bypass the fine material between two crushing stages. Heavy-duty materials should be used, as they will be involved in the classification of very coarse materials.

Heavy Duty

When coarse-grained material needs to be classified, grizzly screens are the first choice. The fact that the first screening panel that meets the coarse material consists of cast or sheet metal grates is very beneficial in terms of reducing spare parts consumption. It prevents timeless stops and shows high performance in terms of efficiency.

In the primary stage, the materials which are placed between the rock feeder and the crusher or between the primary crusher and the secondary crusher are separated and screened.

Due to the coarseness of the fed material, the wire mesh screen cannot withstand working at these stages and must be replaced in a short time. Grizzly screens are the most suitable screen type for these stages.

Thanks to the vibration mechanism that ensures the uniform spread of the fed material, the material advances rapidly and the fine material is easily screened. Thus, the screen performs at full capacity while keeping the productivity at the highest level.

Heavy duty screen bearings are used in the driven mechanism. Drive shaft, pulley and belt selections are made specially.

When screen panel replacement is required, the front chute is opened within minutes with the rail mechanism it has. If it is used as an intermediate screen to feed a machine directly, the screen panel needs to be changed from the back. You will not waste time, thanks to the grease nipple that we extend outside the housing, without having to remove the belt and weight guards for lubricating the bearings.

According to the design of the crushing and screening process, the material on the grid can be fed directly to the crusher without the need for a conveyor, by being coupled to the primary unit or the secondary unit. The material under the grid can also be fed directly to the output conveyor of the crusher or it can be given out with a diverter chute to be added in between.

At the same time, the grizzly screen can be used as a stand-alone equipment without being coupled to a machine. It can successfully operate between two crushing processes with its own chassis, platform, chutes and feeding and output conveyors.