H2B2 Electrolysis Technologies

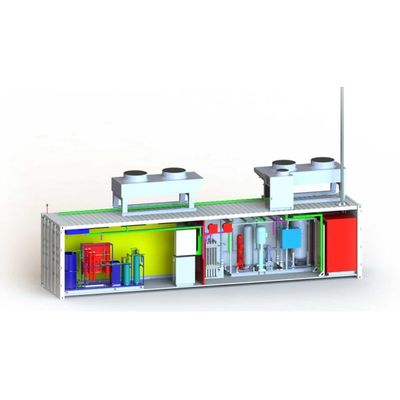

H2B2 - Large Scale Electrolyser

H2B2’s largest-size of electrolysers are able to supply hydrogen from 100 to 600 Nm3/h. These systems are integrated into a 40ft containers. H2B2’s electrolysers are certified and developed according to European or American (depending on customer geography) codes and standards. H2B2 supplies electrolysers with CE marking and, if necessary, ETL stamp (priced separately), as well as required safety studies (HAZOP by default).

Most popular related searches

water treatment plant

demineralized water treatment

demineralized water plant

gas purification

demineralized water

hazardous area

feed water

water treatment

H2S water

electrolyser

Main characteristics

- Electrolysis type: PEM (Proton exchange membrane, caustic free)

- Number of cell stacks: 4

Hydrogen gas production

- Max. nominal hydrogen flow: 800 Nm3/h (1,726 kg/day)

- Hydrogen flow range: 10 – 100%

- Operating pressure: 15 – 40 barg (217-580 psig)

- Hydrogen purity (before gas purification): > 99.9%; < 25 ppm O2; H2O saturated

- Hydrogen purity (after gas purification): 99.999%; < 5 ppm O2; < 5 ppm H2O

Electrical requirements

- Voltage: 3 x 400 VAC ± 10% (3Ph+N) / 3 x 480 VAC ± 10% (3Ph+N)

- Frequency: 50 Hz ± 5% / 60 Hz ± 3%

- Power (BoP + Stacks): 4,130 kW

- Stack consumption: 4.7 kWh/Nm3 H2

- AC power consumption (BoP + stack)(*): 5.1 kWh/Nm3 H2

Feed Water – Demi Water (optional Water Treatment Plant is not included)

- Consumption: < 1 L/Nm3 H2

- Conductivity: > 10 M?cm (< 0.1 uS/cm); TOC < 30 ppb

- Pressure: 2-3 barg (29-43 psig)

- Temperature: +5 ºC to + 40 ºC (+41 ºF to +104 ºF)

Control system

- PLC: Fully automated and unattended with 15″ color touch screen

- Communication: Modbus TCP/IP or Profinet (RJ45 port)

Environmental conditions

- Ambient temperature range: +5 ºC to + 45 ºC (+41 ºF to +113 ºF)

- Humidity: 0 to +95% (non-condensing)

- Air ventilation: Available from a non-hazardous area

- Installation area: Indoor/Outdoor

Dimensions and weight

- Dimensions (LxWxH): 2 x [40ft container (12.0m x 2.4m x 2.9m) (39.4ft x 7.9ft x 9.5ft)]

- Approx. weight: 48,000 kg (99,207 lb)

Standards & regulations

- Compliance: CE, ISO 22734-1 / NFPA 2-2016 & NFPA 70

Other characteristics

- Duty cycle: 100% (24/7)

- Start-up time (from stand-by): < 1 sec

- Cold start time: < 5 min

- Nitrogen Supply System: For each purge, consumption is <0.2 kg at 3 barg (to be supplied by the customer).

- Instrumentation air System: Consumption 7 Nm3/h at 10 barg (to be supplied by the customer).

Main characteristics

- Electrolysis type: PEM (Proton exchange membrane, caustic free)

- Number of cell stacks: 3

Hydrogen gas production

- Max. nominal hydrogen flow: 600 Nm3/h (1,290 kg/day)

- Hydrogen flow range: 10 – 100%

- Operating pressure: 15 – 40 barg (217-580 psig)

- Hydrogen purity (before gas purification): > 99.9%; < 25 ppm O2; H2O saturated

- Hydrogen purity (after gas purification): 99.999%; < 5 ppm O2; < 5 ppm H2O

Electrical requirements

- Voltage: 3 x 400 VAC ± 10% (3Ph+N) / 3 x 480 VAC ± 10% (3Ph+N)

- Frequency: 50 Hz ± 5% / 60 Hz ± 3%

- Power (BoP + Stacks): 3,100 kW

- Stack consumption: 4.7 kWh/Nm3 H2

- AC power consumption (BoP + stack): 5.1 kWh/Nm3 H2

Feed Water – Demi Water (optional Water Treatment Plant is not included)

- Consumption: < 1 L/Nm3 H2

- Conductivity: > 10 M?cm (< 0.1 uS/cm); TOC < 30 ppb

- Pressure: 2-3 barg (29-43 psig)

- Temperature: +5 ºC to + 40 ºC (+41 ºF to +104 ºF)

Control system

- PLC: Fully automated and unattended with 15″ color touch screen

- Communication: Modbus TCP/IP or Profinet (RJ45 port)

Environmental conditions

- Ambient temperature range: +5 ºC to + 45 ºC (+41 ºF to +113 ºF)

- Humidity: 0 to +95% (non-condensing)

- Air ventilation: Available from a non-hazardous area

- Installation area: Indoor/Outdoor

Dimensions and weight

- Dimensions (LxWxH): 2 x [40ft container (12.0m x 2.4m x 2.9m) (39.4ft x 7.9ft x 9.5ft)]

- Approx. weight: 45,000 kg (99,207 lb)

Standards & regulations

- Compliance: CE, ISO 22734-1 / NFPA 2-2016 & NFPA 70

Other characteristics

- Duty cycle: 100% (24/7)

- Start-up time (from stand-by): < 1 sec

- Cold start time: < 5 min

- Nitrogen Supply System: For each purge, consumption is <0.2 kg at 3 barg (to be supplied by the customer).

- Instrumentation air System: Consumption 7 Nm3/h at 10 barg (to be supplied by the customer).

Main characteristics

- Electrolysis type: PEM (Proton exchange membrane, caustic free)

- Number of cell stacks: 2

Hydrogen gas production

- Max. nominal hydrogen flow: 400 Nm3/h (860 kg/day)

- Hydrogen flow range: 10 – 100%

- Operating pressure: 15 – 40 barg (217-580 psig)

- Hydrogen purity (before gas purification): > 99.9%; < 25 ppm O2; H2O saturated

- Hydrogen purity (after gas purification): 99.999%; < 5 ppm O2; < 5 ppm H2O

Electrical requirements

- Voltage: 3 x 400 VAC ± 10% (3Ph+N) / 3 x 480 VAC ± 10% (3Ph+N)

- Frequency: 50 Hz ± 5% / 60 Hz ± 3%

- Power (BoP + Stacks): 2,060 KW

- Stack consumption: 4.7 kWh/Nm3 H2

- AC power consumption (BoP + stack): 5.1 kWh/Nm3 H2

Feed Water – Demi Water (optional Water Treatment Plant is not included)

- Consumption: < 1 L/Nm3 H2

- Conductivity: > 10 M?cm (< 0.1 uS/cm); TOC < 30 ppb

- Pressure: 2-3 barg (29-43 psig)

- Temperature: +5 ºC to + 40 ºC (+41 ºF to +104 ºF)

Control system

- PLC: Fully automated and unattended with 15″ color touch screen

- Communication: Modbus TCP/IP or Profinet (RJ45 port)

Environmental conditions

- Ambient temperature range: +5 ºC to + 45 ºC (+41 ºF to +113 ºF)

- Humidity: 0 to +95% (non-condensing)

- Air ventilation: Available from a non-hazardous area

- Installation area: Indoor/Outdoor

Dimensions and weight

- Dimensions (LxWxH): 40ft container (12.0m x 2.4m x 2.9m) (39.4ft x 7.9ft x 9.5ft)

- Approx. weight: 20,000 kg (44,092 lb)

Standards & regulations

- Compliance: CE, ISO 22734-1 / NFPA 2-2016 & NFPA 70

Other characteristics

- Duty cycle: 100% (24/7)

- Start-up time (from stand-by): < 1 sec

- Cold start time: < 5 min

- Nitrogen Supply System: For each purge, consumption is <0.2 kg at 3 barg (to be supplied by the customer)

- Instrumentation air System: Consumption 7 Nm3/h at 10 barg (to be supplied by the customer)

Main characteristics

- Electrolysis type: PEM (Proton exchange membrane, caustic free)

- Number of cell stacks: 1

Hydrogen gas production

- Max. nominal hydrogen flow: 200 Nm3/h (430 kg/day)

- Hydrogen flow range: 10 -100%

- Operating pressure: 15 – 40 barg (217-580 psig)

- Hydrogen purity (before gas purification): 99.9%; < 25 ppm O2; H2O saturated

- Hydrogen purity (after gas purification): 99.999%; < 5 ppm O2; < 5 ppm H2O

Electrical requirements

- Voltage: 3 x 400 VAC ± 10% (3Ph+N) / 3 x 480 VAC ± 10% (3Ph+N)

- Frequency: 50 Hz ± 5% / 60 Hz ± 3%

- Power (BoP + Stack): 1,030 kW

- Stack consumption: 4.7 kWh/Nm3 H2

- AC power consumption (BoP + stack): 5.1 kWh/Nm3 H2

Feed Water – Demi Water (optional Water Treatment Plant is not included)

- Consumption: < 1 L/Nm3 H2

- Conductivity: > 10 M?cm (< 0.1 uS/cm); TOC < 30 ppb

- Pressure: 2-3 barg (29-43 psig)

- Temperature: +5 ºC to + 40 ºC (+41 ºF to +104 ºF)

Control system

- PLC: Fully automated and unattended with 15″ color touch screen

- Communication: Modbus TCP/IP or Profinet (RJ45 port)

Environmental conditions

- Ambient temperature range: +5 ºC to + 45 ºC (+41 ºF to +113 ºF)

- Humidity: 0 to +95% (non-condensing)

- Air ventilation: Available from a non-hazardous area

- Installation area: Indoor/Outdoor

Dimensions and weight

- Dimensions (LxWxH): 40ft container (12.0m x 2.4m x 2.9m) (39.4ft x 7.9ft x 9.5ft)

- Approx. weight: 18,000 kg (39,683 Ib)

Standards & regulations

- Compliance: CE, ISO 22734-1 / NFPA 2-2016 & NFPA 70

Other characteristics

- Duty cycle: 100% (24/7)

- Start-up time (from stand-by): < 1 sec

- Cold start time: < 5 min

- Nitrogen Supply System: For each purge, consumption is <0.2 kg at 3 barg (to be supplied by the customer)

- Instrumentation air System: Consumption 7 Nm3/h at 10 barg (to be supplied by the customer)

Main characteristics

- Electrolysis type: PEM (Proton exchange membrane, caustic free)

- Number of cell stacks: 1

Hydrogen gas production

- Max. nominal hydrogen flow: 100 Nm3/h (215 kg/day)

- Hydrogen flow range: 10 -100%

- Operating pressure: 15 – 40 barg (217-580 psig)

- Hydrogen purity (before gas purification): > 99.9%; < 25 ppm O2; H2O saturated

- Hydrogen purity (after gas purification): 99.999%; < 5 ppm O2; < 5 ppm H2O

Electrical requirements

- Voltage: 3 x 400 VAC ± 10% (3Ph+N) / 3 x 480 VAC ± 10% (3Ph+N)

- Frequency: 50 Hz ± 5% / 60 Hz ± 3%

- Power (BoP + Stacks): 515 kW

- Stack consumption: 4.7 kWh/Nm3 H2

- AC power consumption (BoP + stack): 5.1 kWh/Nm3 H2

Feed Water – Demi Water (optional Water Treatment Plant is not included)

- Consumption: < 1 L/Nm3 H2

- Conductivity: > 10 M?cm (< 0.1 uS/cm); TOC < 30 ppb

- Pressure: 2-3 barg (29-43 psig)

- Temperature: +5 ºC to + 40 ºC (+41 ºF to +104 ºF)

Control system

- PLC: Fully automated and unattended with 15″ color touch screen

- Communication: Modbus TCP/IP or Profinet (RJ45 port)

Environmental conditions

- Ambient temperature range: +5 ºC to + 45 ºC (+41 ºF to +113 ºF)

- Humidity: 0 to +95% (non-condensing)

- Air ventilation: Available from a non-hazardous area

- Installation area: Indoor/Outdoor

Dimensions and weight

- Dimensions (LxWxH): 40ft container (12.0m x 2.4m x 2.9m) (39.4ft x 7.9ft x 9.5ft)

- Approx. weight: 18,000 kg (39,683 lb)

Standards & regulations

- Compliance: CE, ISO 22734-1 / NFPA 2-2016 & NFPA 70

Other characteristics

- Duty cycle: 100% (24/7)

- Start-up time (from stand-by): < 1 sec

- Cold start time: < 5 min

- Nitrogen Supply System: For each purge, consumption is

- Instrumentation air System: Consumption 7 Nm3/h at 10 barg (to be supplied by the customer)