- Home

- Companies

- Zhongshan Amitime Electric Co. Ltd

- Products

- HeatStar System

HeatStar System

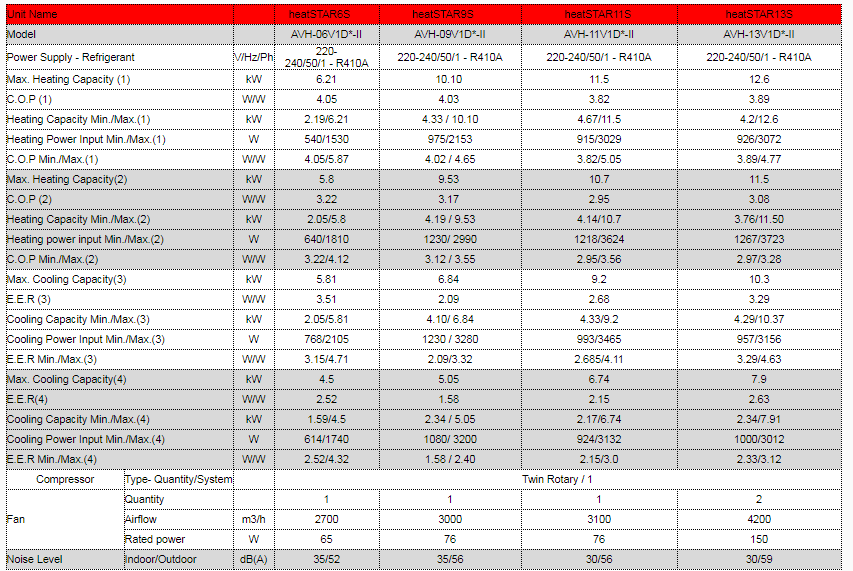

Amitime`s heatSTAR system has been developed with the idea in mind for maximum possible energy savings, through its ultra high SCOP rating and quiet operation. Latest development in DC inverter technologies and their application in various internal components; including compressor, fan, and water pump, has been the major player in the success of our heatSTAR line.

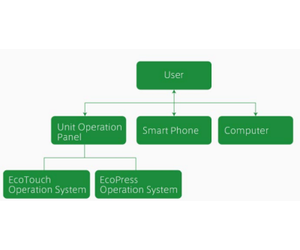

Operation Panel: Installed on the unit, the panel provides two separate operation systems for the user to choose; EcoTouch and EcoPress. Refer to introductions in following pages for details.

Smart Phone: By using Amitime APP or APK, users can access to the basic settings remotely via Iphone or Andriod smart phones.

Computer: Users via computer can login Amitime web server remotely and change any setting, view historic running status, as well as update the software from anywhere remotely.

In addition to the listed control modes, Amitime` s heatSTAR can also be put under the control of a 8MS (Building Management System) controller through a standard MODBUS communication link.

Structure of heatSTAR software has been divided into, "Application Controller" and "Compressor System Controller" for easy extention purposes. By using your BMS system to replace our "Application Controller" and connecting it directly to our "Compressor System Controller", you can easily have heatSTAR unit integrate into any BMS controller.

"Compressor System Controller*, handles all the compressor controls and protections by following the instructions from the BMS (working mode, compressor speed etc.,) while keeping its compressor protections in higher priority. In case a protection is triggered, system will switch to a safe mode automatically and send related feedback to the BMS controller.