- Home

- Companies

- Advance Hydrau Tech Pvt Ltd.

- Products

- AH - Heavy-Duty Triple Action Baling ...

AH - Heavy-Duty Triple Action Baling Press Machine

The compressing action of Triple action metal baler works on the metal scrap from three directions. This efficient and powerful triple compression scrap baling press machine, compacts the metal scrap from the top, sideways and longitudinally resulting in highly dense and optimally compacted bales. Advance Hydrau Tech manufactures triple action Jumbo plus balers, Jumbo balers, mini balers depend upon the scrap quantity and requirement of the customer.

All the balers are ideal for customers looking to bale medium to large quantities of all types of ferrous and non-ferrous metal scrap, stainless steel, aluminium and copper scrap. Advance Hydrau Tech’s metal baler (triple compression baler) is a heavy-duty fully automatic baler and can easily process up to 10 tons/hr of metal scrap.

The heavy-duty triple action baling press machine can be used to process a variety of materials including metal offcuts, machine chips, automobile skeletons, steel and aluminium used beverage cans (UBCs), LMS and CRC scrap, sheet, stampings, wires, tubing, and white goods.

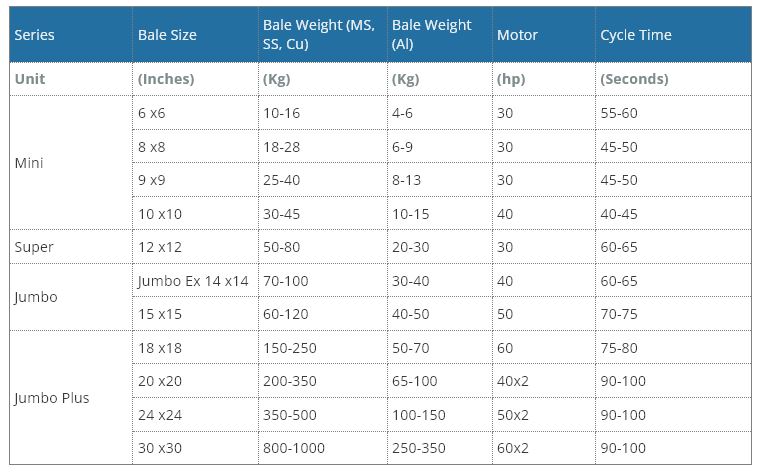

Customer satisfaction with this three ram metal baler is guaranteed owing to its excellent operating costs, flexibility, and reliability. The technology used in our triple action baler allows for minimal power consumption while giving its maximum output which results in highly efficient operation. We can customize the bale size and density as per the customer’s requirement. The triple-action baler can produce bales of size ranging from 6”x6” up to 30”x30” and weighing 10 kg to 1 ton.

- Low overall operating cost

- High productivity

- Super high-density bales

- Increased speed of movements

- Lower cycle times through the use of high-pressure pumps

- Low energy consumption

- Easy installation

- Robust design

- PLC-controlled

- Available in automatic as well as semi-automatic variants

- Highly efficient hydraulic systems

- Lubrication system for minimum wear and tear

- Online chiller for cooling the hydraulic oil so that machine can be run for long hours

- Includes Check Valves and Limit Valves to avoid any accident

- Replaceable wear-resistant plates supplied

- Shearing blades on the edges of the top lid and chamber are available for shearing oversized material

- Large volume of chargebox

- Comes with wired remote control

- Additional scrap feeding hopper can be provided for enhancing the productivity of the baler

- Multi-information PLC display for easy operation and troubleshooting

- Wireless Remote Control

- Customization of the Baling Press as per your specific requirements

- All the above models are available as Top Ejection, Turn Out and Side Ejection

- Air radiator for oil cooling

- Feeding Hopper

- Online Oil Filteration System

- Wireless Remoter

* Specifications are indicative and are subject to change as per customer’s requirement and technical advancements.

* Accessories shown in the image are not necessary to form part of the actual machine.

* All dimensions, weights and cycle time mentioned are approximate.

* Output depends on the type of the scrap material fed, feed rate and operator skills.