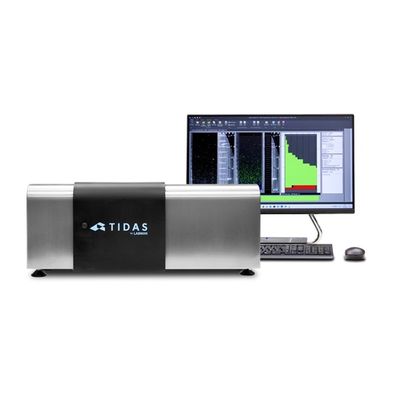

Labman TIDAS - Hegman Gauge Analyser

Due to its robust, low-maintenance design, super-sharp imaging, customisability and versatility, TIDAS has become the go-to system for grind gauge/grindometer testing. Due to its robust, low-maintenance design, super-sharp imaging, customisability and versatility, TIDAS has become the go-to system for grind gauge/grindometer testing.

TIDAS automates the analysis of a wide range of products using a Hegman gauge. Fineness of grind is determined objectively, removing operator variation and ensuring reproducibility. Each reading takes less than 20 seconds. If you use a Hegman gauge in your process, you will benefit from TIDAS.

A traditional Hegman test is entirely subjective and prone to human variance - from the drawdown application itself, to lighting conditions, eyesight health and simple human judgement. TIDAS captures a raw image of the dispersion which is digitally analysed. The exact number of particles per micron slice are counted, which provides a defined and repeatable reading.

- Have confidence in a single reading

- Each reading takes less than 20 seconds

Many products from the coatings industry begin life as a powder or pigment. These raw ingredients are ground down to standard which means running costly factory processes. Represented by a typical, exponential grind curve, even small reductions in particle size can take a very long time to achieve. Small variations from human error, can translate to huge wasted costs from unnecessary over processing. Determining the optimum grinding time eliminates this risk.

- Determine optimum processing time for pigments and powders

- Eliminate over-processing costs without compromising quality

- Free up factory equipment to continue with other work

TIDAS is compatible with paints, resins, inks, adhesives, battery materials, foods, cosmetics and much more. The TIDAS software is designed to eliminate dust, bubbles and foaming from the dispersion. It can also robustly take readings from clear and metallic materials which are notoriously difficult to rate by eye, owing to the dark field illumination technique used to capture the image.

- Robustly analyse clear and metallic materials, notoriously difficult to rate by eye

- Compatible with any liquid sample, making it a key QC tool for various industries

Applicable to many applications

Battery materials, paints, pigments, inks, resins, sealants, graphene, polymers, cosmetics, food, ceramics, solder pastes, additives, minerals, clear and metallic liquids and much more.

Tried and tested

TIDAS was developed over 25 years ago and has gone through several iterations, each honing its performance and reliability. It now operates in over 40 countries for a range of companies including Akzo Nobel, Venator and BASF.

Compatible & customisable

TIDAS’s dedicated software can be customised to match your requirements allowing you to set ratings and more. TIDAS works with a wide range of gauge sizes to suit your existing workflow.

Owing to an intelligent but simple design, TIDAS uses a combination of technologies to produce the most precise readings, time and time again.

Precise image capture

Capture super-sharp images using a line scan camera

Dark field illumination

Intelligent technology to highlight the particles you want, not the ones you don't.

Customised software

Configure the algorithm to take readings in line with your standards

Eliminate human variance

What does a little variance matter? A lot, actually! Find out why.

There are many things which humans are better at than robots, but taking measurements by eye, is not one of them. Labman conducted a test to establish the typical variation from user to user, when taking readings manually from a Hegman gauge. To read about the results of our experiment, and the impact this has on production costs, follow this link.