- Home

- Companies

- Heidelberg Instruments Mikrotechnik ...

- Products

- Heidelberg Instruments - Model MLA 150 ...

Heidelberg Instruments - Model MLA 150 -Advanced Maskless Aligner

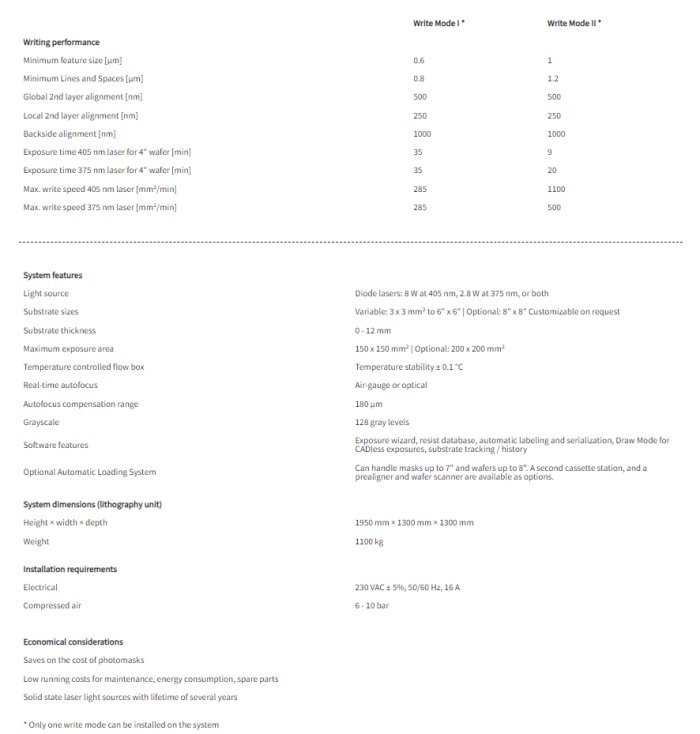

The fastest Maskless Aligner for R&D, rapid prototyping and small production volumes, designed for binary lithography. The Maskless Aligner MLA 150 is a state-of-the-art maskless lithography tool. Areas of application include nanofabrication of quantum devices (2D materials, semiconductor materials, nanowires, etc.) MEMS, micro-optical elements, sensors, actuators, MOEMS and other devices for materials and life sciences. Depending on the application, the MLA 150 patterns high-resolution, high aspect ratio, and even simple grayscale structures.

Our Maskless Aligner series, first introduced in 2015, is now firmly established as an alternative to the traditional mask aligner, fully eliminating the need for masks. The maskless approach leads to significantly reduced cycle times. Any design modifications can be quickly implemented by simply changing the CAD layout. The system also features fast automated front- and backside alignment procedures and outstanding speed: Exposing an area of 100 x 100 mm² with structures as small as 1 µ takes less than 10 minutes.

The 150th MLA 150 installed in 2022: The MLA 150 Success Story

Perfect for Multi-user Facilities

Less than 1 h training to fully qualify as a user

Fast and Accurate Alignment

250 nm front alignment, backside alignment, alignment error compensation

Flexible

Two lasers can be installed simultaneously on the same system to expose the whole range of photoresist

Low Operation Costs and Easy Maintenance

10-20 years of laser lifetime

Direct-write Lithography

No mask-related costs, effort, or security risks

Grayscale Mode

For simple 2.5D structures

Exposure Quality

Edge roughness 60 nm; CD uniformity 100 nm; 40 nm address grid; autofocus compensation for warped/corrugated substrates

User-friendly

Specifically designed software and workflow make the tool operation fast and easy

Exposure Speed

150 mm wafer in