Heidelberg Instruments - Model µMLA -Tabletop Maskless Aligner

The tabletop µMLA system is state-of-the-art in maskless technology built on the renowned µPG platform – the most sold tabletop maskless system worldwide. It is a perfect entry-level research and development (R&D) tool for virtually any application requiring microstructures. Typical examples are microfluidics (cell sorting devices, lab-on-a-chip), small-scale mask-writing, micro-optics and microlens arrays, sensors, MEMS, contacting 2D materials and fan-out electrodes, etc.

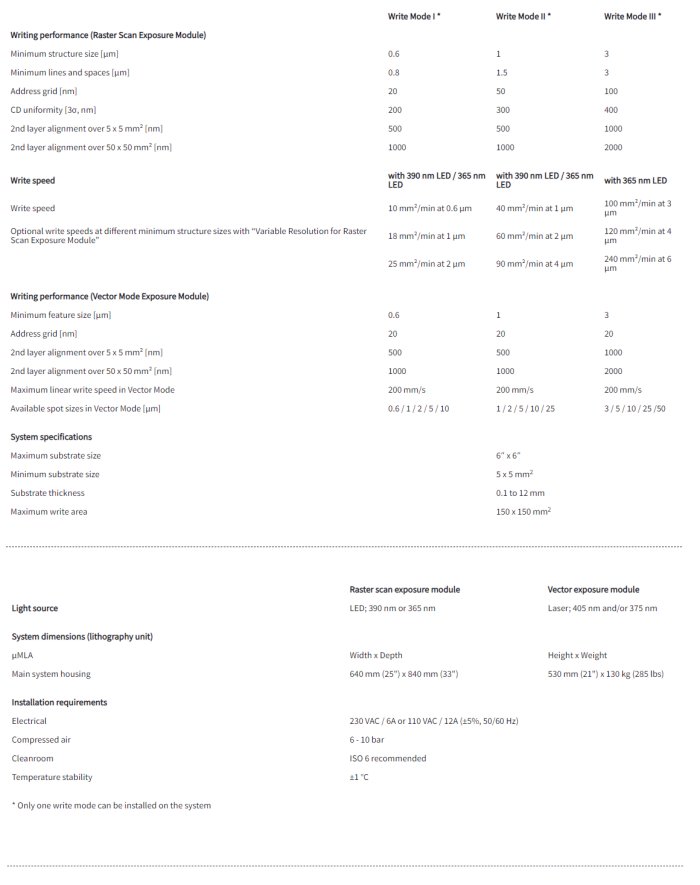

The µMLA is a flexible and customizable tool, and offers two exposure modes. The standard µMLA uses the Raster Scan Exposure Mode for exposures, which is fast and provides excellent image quality and fidelity, while the write time is independent of structure size of pattern density. The optional Vector Scan Mode is designed for patterning continuous smooth curves such as waveguides in a faster and more accurate way. Three optical setups offer a choice of variable resolution and throughput. Each allows easy switching between different resolution and speed configurations to optimize exposure for a given application. The Draw Mode enables straightforward ad-hoc modifications to existing structures and electrical contacts to nanowires or 2D materials. The grayscale exposure mode allows the creation of complex 2.5 structures such as micro-optical devices. With its small footprint, the µMLA fits on a regular table.

Direct-write Lithography

No mask-related costs, effort, or security risks

Exposure Quality

Edge roughness raster mode 100 nm; vector mode 30 nm; CD uniformity 200 nm

Exposure Speed

4″ wafer in 90 minutes

Grayscale Lithography

With up to 128 gray levels, the grayscale exposure capability is part of the standard configuration

Small Footprint

640 mm x 840 mm x 530 mm / 25″ x 33″ x 21″ – the smallest tabletop maskless lithography tool

Flexible Configuration

Choice of exposure wavelength; a choice of Raster and Vector Scan Modules

Flexible Use

Software enables easy switching for variable resolution and throughput speeds

User-friendly

Intuitive software and tool operation; easy handling of small samples

Plug-and-play Setup

Simplified plug-and-play installation reduces overall implementation time and saves costs

Raster Scan Exposure Mode

Fast with excellent image quality and fidelity; write time is independent of structure size or pattern density. LED light source at 365 nm or 390 nm

Vector Scan Exposure Mode

Patterning continuous structures consisting of curved lines – where smooth contours are required. Laser light source at 405 nm and/or 375 nm

Three Optical Setups

Min. resolution of 0.6 µm, 1 µm and 3 µm; variable resolution within each mode

Optional Overview Camera

Fast and easy location of alignment marks or other features of interest on substrate

Glovebox Integration

Glovebox for patterning of sensitive materials in a controlled Nitrogen environment

Draw Mode

Import and overlay of BMP files on top of the real-time microscope image — as in a virtual mask aligner; simple lines and shapes can be drawn into the real-time camera image for immediate exposure

Optical Autofocus

Perfect exposure of small samples (

Exposure Area

Can be upgraded from 100 x 100 mm2 to 150 x 150 mm2

Choice of Exposure, Wavelength and Source

Raster Scan Mode: LED light source at 365 nm or 390 nm. Vector Scan Mode: Laser light source at 405 nm and/or 375 nm