- Home

- Companies

- Henan Doing Environmental Protection ...

- Products

- Henan-Doing - Fully Continuous Waste ...

Henan-Doing - Fully Continuous Waste Tyre to Fuel Oil Recycling Plant

Fully continuous waste tyre to fuel oil recycling plant is a kind of high efficiency pyrolysis plant developed by Doing Group on the basis of intermittent pyrolysis plant. In order to better meet the needs of customers, the fully continuous waste tyre to fuel oil recycling plant adopts PLC control system, can continuously feed, continuously discharge slag, is a continuous operation of pyrolysis production line. Both in terms of operating costs and efficiency to meet the requirements of customers.

Now I will mainly introduce fully continuous waste tyre to fuel oil recycling plant.

Working process of fully continuous waste tyre to fuel oil recycling plant:

Tyre pretreatment

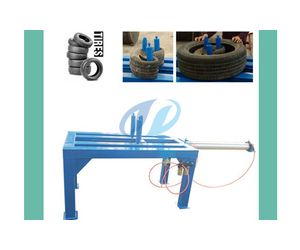

Waste tyre through the steel wire drawing machine to pull out the steel wire in the waste tyre, and then put the tyre into the tyre crusher. After the treatment of the tyre crusher, the tyres are processed into 3-5 cm pieces.

Feeding

Shredded tyres are fed into the reaction system of fully continuous waste tyre to fuel oil recycling plant by an auto-feeder. The entire feeding process is sealed. Fully continuous waste tyre to fuel oil recycling plant using PLC control system, with high degree of automation, feeding no longer need manual operation.

Continuous pyrolysis

The pyrolysis process is controlled by PLC, PLC system accurately calculates the reaction time

which can ensure that shredded tyres is fully cracked.

Cooling

The pyrolyzed oil gas passes through the circulating water cooling system and becomes liquid oil.

Oil product collection

Liquid oil is collected into the tank. No fireworks around the oil tank.

Discharge carbon black

After the reaction, carbon black will be automatically discharged from the other end by a unique slag discharge system.

- Accurate calculation system can ensure that the waste tyre is fully cracked to improve the oil yield.

- Continuous feeding, continuous slag discharge, having very high production efficiency.

- PLC control system can saves manpower.

- Single plant has large processing capacity and takes up less space.