- Home

- Companies

- RunDry Evaporators

- Products

- RunDry - Model 70-300GPH - High ...

RunDry - Model 70-300GPH -High Capacity Wastewater Evaporator System

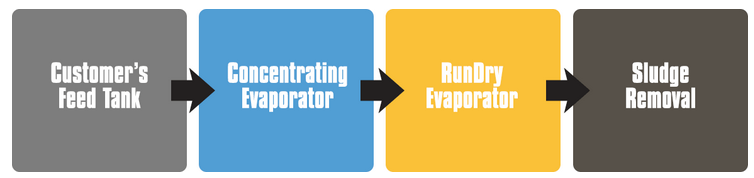

A unique 2-step process which starts with a Concentrating Evaporator that will reduce the volume of your water by approximately 90%. We then take it one more step by transferring that concentrate over to a RunDry Evaporator which will evaporate the rest of the water, leaving just the contaminants behind.

- Metalworking

- Metal Finishing

- Transportation

- Scrap Metal Recycling

- Printing

- Ultra-filter

- Micro-filtration

- Reverse Osmosis

- Ion exchange

- Chemical Vat Cleaning

- Gas-Line Waters

- Ethylene Glycol

- Propylene Glycol

- Nuclear Waste Wash Water

- Pharmaceuticals

Benefits of a RunDry Evaporator

Numerous companies pay for a waste hauler to take their dirty water away. If these companies would switch over to using RunDry Evaporators™ they would realize these benefits:

Reduce Cost:

It typically cost $1.00 to $2.00 to have wastewater hauled away. RunDry evaporator can save companies a significant amount of their operating cost because they can evaporate waste for $0.08 – $0.25. Many companies have ROI’s of 1 year or less.

Elimination of Storage:

If a waste hauler is used, the wastewater must be accumulated in a storage tank or drums until there is sufficient volume to warrant the trip for the waste hauler. This takes up valuable floor space in the facility. There is also a potential for spills or leaks. RunDry Evaporators™ eliminate all of this!

Reduced Liability:

When a company generates wastewater they are liable for this wastewater from cradle to grave. Therefore, if the waste hauler’s truck leaves your facility and has an accident that causes the wastewater to spill on the road, the company that generated that wastewater will have to pay for the clean up. A RunDry Evaporator™ eliminates this liability.

Our competitors often have a burner tube in their wastewater tank which makes it very difficult to clean out the oil or sludge that is below it. Our wastewater tank is clear with no obstructions, making it very easy to clean. In some cases where there is only oil remaining after evaporating the wastewater, it can be pumped out to a waste oil tank and sold to a used oil reclaimer.

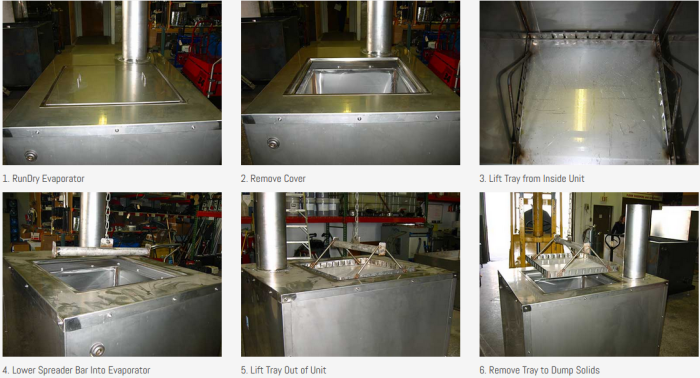

If your wastewater evaporates down to a dry solid or a sludge, we have an option that makes it even easier to clean the unit out – it is a sludge liftoff tray. This stainless tray is placed in the bottom of the evaporator before you start to fill it with the wastewater. Then during the RunDry™ evaporation process, the solids and sludge will settle to the bottom of the wastewater tank and land in the tray. Once your evaporation processing period is finished and the tank has RunDry™, the sludge tray can be lifted out of the evaporator and the sludge can be scraped off into a dumpster.

Wastewater evaporators have two areas where the selection of construction materials can play a big role in the effective life of the unit: the exterior housing and the interior water tank.

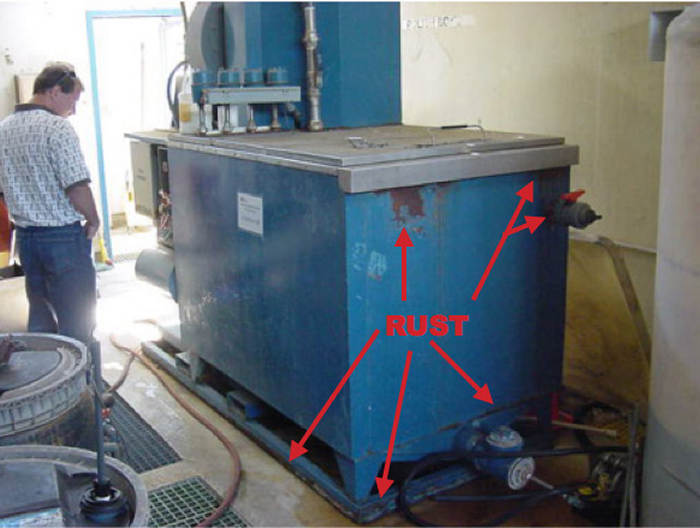

The Exterior Housing

Many of our competitors offer their wastewater evaporators with painted carbon steel as the exterior housings. They do this because it allows them to lower their initial price in an effort to get your business. The problem is that wastewater evaporators are a wet environment and the paint job can get scratched during use. The combination of these two things can result in rust forming on the housing as can be seen in this picture of a competitor’s two year old wastewater evaporator.

RunDry Evaporators have taken the high road and use 304 stainless steel for our exterior housing. This may result in our units having a higher initial cost, however a RunDry Evaporator will stay in service much longer then our competitors. Our life time cost is much lower and our unit look great thought their life time which can be seen in the 2 year old RunDry Evaporator seen in this picture.

The Interior Water Tank

Many of our competitors offer their water tanks in carbon steel and as a result they rust out and have a short life. RunDry Evaporators again went the quality route and made our standard 316L stainless steel. We even offer special alloys for high chloride applications.