- Home

- Companies

- MUTAG (Multi Umwelttechnologie AG)

- Products

- Mutag BioChip 30TM - High-Performance ...

Mutag BioChip 30TM - High-Performance Water Treatment Biofilm Carrier

The Mutag BioChip was developed in 2008 and is being manufactured in our company-owned production facility.

A product made from experience.

From the experience gained in the large-scale application of different biofilm carrier types available on the market, the Mutag BioChip™ was finally developed internally at Mutag.

Negative characteristics of other carrier types were

- small protected surface area

- mechanical destruction due to breakage or abrasion

- clogging due to dead biomass, reduction of diffusion

- bad motion characteristics with attached biomass

- high cost

For reasons of quality assurance, product optimization and independence, an own production was established in Germany on developing the Mutag BioChip™.

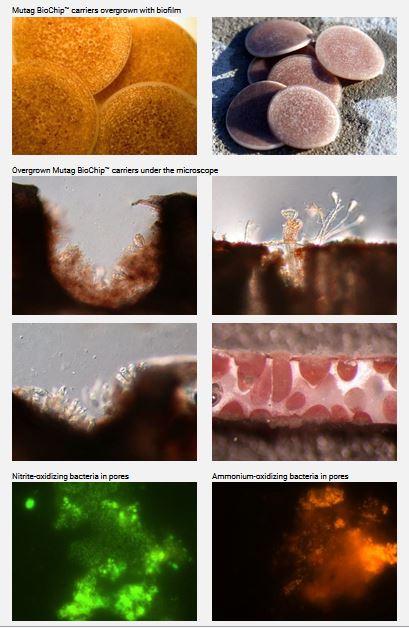

The quality as well as the structure of the surface and the pore system are regularly examined by an external institute for physical nanostructures.

During the production process the pore quality, shape and density of the material are checked.

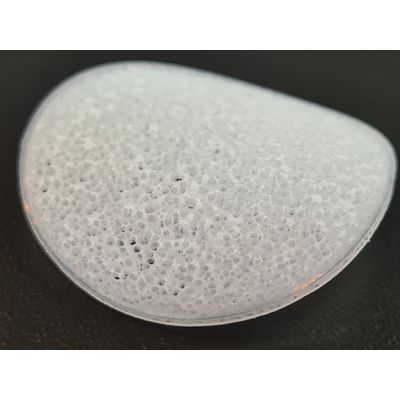

- Circular up to Ø 30 mm (1 1/4“)

- Thickness ~ 1.1 mm ( ~ 0.04")

- Virgin PE material

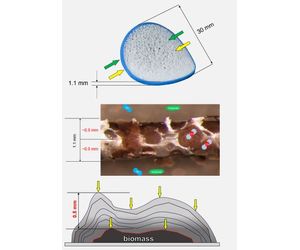

- Active surface area up to 5,500 m²/m³ (up to 1,677 ft²/ft³)

- Biomass concentration specified acc. to the application purpose.

A product in need of explanation, providing a high level of quality for highest standards.

Optimal biomass concentrations for maximum removal rates.

During the development of the Mutag BioChip™, pilot trials had been performed in numerous fields of application or in extensive laboratory-scale trials using different production effluents, in which the efficiency of the carrier was ascertained.

As known, not solely the surface area but rather the amount of active biomass immobilized on the carrier is crucial when it comes to the evaluation of the carrier‘s efficiency.

For this reason, it is necessary to consider the active biomass.

The Mutag BioChip™ has a homogeneous outer ring as buffer zone, protecting the pore structure from potential damage/abrasion/cuts.

Due to its low net weight, the kinetic energy is also that low so any mechanical wear is prevented.

The surface and pore structure is evenly distributed on a diameter of up to 30 mm (1 1/4“) and due to its openings it provides an optimal habitat for the microorganisms.

Thicker biofilms on the exterior surface are abraded by shear forces.

The pores of the Mutag BioChip™ are permanently filled with active biomass since substrate and/or oxygen can diffuse into the biofilms down to a depth of approx. 0.5 mm (0.02") on both sides of the chips. This is made possible by the chip thickness of approx. 1.1 mm (0.04").

Here you see a cross section of a chip. The diffusion depth is approx. 0.5 mm (0.02").

The diffusion depth is approx. 0.5 mm (0.02"); any biomass located deeper than that is not being supplied sufficiently and becomes anaerobic.

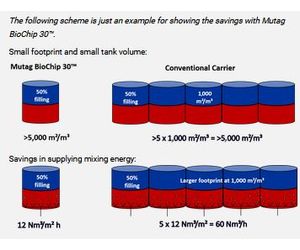

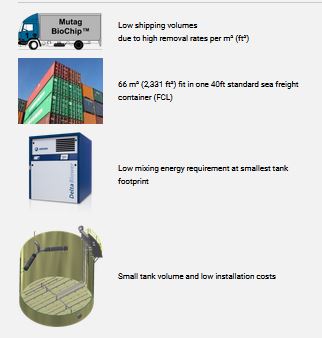

For a price comparison of the calculated carrier media quantity, shipping charges, tank size and mixing energy must be considered as basis.

Do not compare €/m³ with €/m³ ($/ft³ with $/ft³).

Please note!

It does happen rather often that prices per m³ (per ft³) of carriers are compared with each other. Frequently, suppliers of carrier media only provide assumptions which cause confusion, or profound proof is missing: „we see a biologically active surface area of …“

Only one who calculates based on the facts will in turn recognize the savings provided by the Mutag BioChip™.

Fact-check

It is highly important to request your respective biofilm carrier suppliers to communicate to you the required carrier media quantity, the tank size, the process air and oxygen requirement as well as the shipping charges for CIF delivery for your MBBR project.

Subsequently, you will be in the position to make the comparison.

Do in no way compare €/m³ with €/m³ ($/ft³ with $/ft³).

Hint: The risk is being redeployed by the person that is not able to give full specification details.

From the experience gained in the large-scale application of different biofilm carrier types available on the market, the Mutag BioChip™ was finally developed internally at Mutag.

Negative characteristics of other carrier types were:

- small protected surface area

- mechanical destruction due to breakage or abrasion

- clogging due to dead biomass, reduction of diffusion

- bad motion characteristics with attached biomass

- high cost