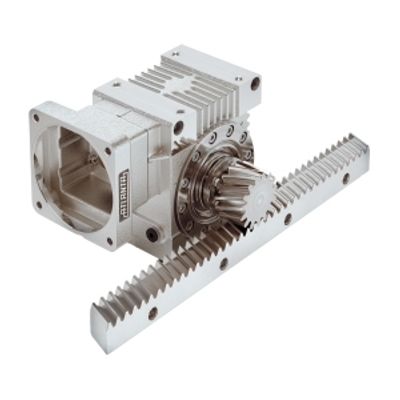

ATLANTA - High-Precision Rack and Pinion Drive Systems

The high-precision rack and pinion drive systems are engineered for applications demanding exceptional accuracy and durability. These systems incorporate precision planetary and servo-worm reducers, capable of achieving backlash levels as low as one arc-minute. The design ensures robust support through hardened and ground pinions which operate seamlessly with hardened and ground racks. Ideal for axis drives, traveling gantries, CNC routers, and robotic systems, these drives handle heavy loads and demanding duty cycles efficiently. Utilizing continuous grease lubrication, the automatic lubrication systems are recommended for maintaining gear integrity and extending operational lifetime. The systems offer various precision levels, with rack pitch errors ranging from 0.012 mm to 0.036 mm per meter. Furthermore, the reducers, available with ratios from 4.75:1 to 52:1, come in multiple configurations to suit specific application needs. For applications where eliminating backlash is critical, dual pinion setups with electronic preloading are recommended. These systems are pivotal in delivering precise and repeatable motion control in advanced industrial settings.

These systems utilize our our precision Planetary and Servo-Worm Reducers, which have backlash levels down to one arc-minute, to rigidly support and drive a hardened & ground pinion. The rack used in these systems is also hardened & ground.

These drives are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers and material handling systems. Heavy loads and duty cycles can be easily handled with these drives.

Our Automatic Lubrication Systems are highly recommended for use with these drives, providing continuous grease lubrication to the rack & pinion tooth flanks to preserve the quality and lifetime of the gearing.