Kopar - High Pressure Pneumatic Conveyor

Pneumatic conveying is one of the most efficient and economical ways of handling granular, grainy, powdery bulky process industry materials. Our solutions guarantee low operational costs, high capacity and versatility with layout.

We have almost 50 years of experience concerning numerous industrial pneumatic conveying projects, including engineering, manufacturing, testing, erection, commissioning, and life cycle services.

Based on our experience in different material behaviour, we have developed our technology to meet our customer’s highest requirements.

We also constantly test new materials in our own testing facility to learn more on pneumatic conveying and changing characteristics of bulk materials.

With hundreds of delivered pressure conveyors in the past decade, our reference list includes thousands of delivered pneumatic conveyors since the 1970s.

The long history makes us also humble, we know each application can be unique and therefore we face every case with the same enthusiasm and precision as the first one all those years back.

Suitable usage cases for pressure conveyors

Pressure conveyors are suitable for several industries: energy and power industries, metallurgical smelters, and mineral and chemical industries.

- maximize the availability by minimizing the risk of any unexpected shutdowns and maintaining a smooth operation

- maximize the lifetime of the wear parts

- minimize the operational and maintenance expenses.

Therefore, we offer our unique specialists and knowhow to update the equipment functions to meet required performance variations and beyond.

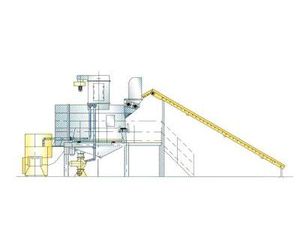

Automatic station is very efficient - it can discharge even 600 sacks in hour. It`s operation is dust free because the system is closed.

Components

- Inclined belt conveyor

- Automatic bag discharger

- Vibrating screen bottom

- Automatic bag baler

- Exhaust air filter

- Pneumatic or mechanical material transfer