- Home

- Companies

- Watertronics, Inc.

- Products

- Watertronics - Horizontal Centrifugal ...

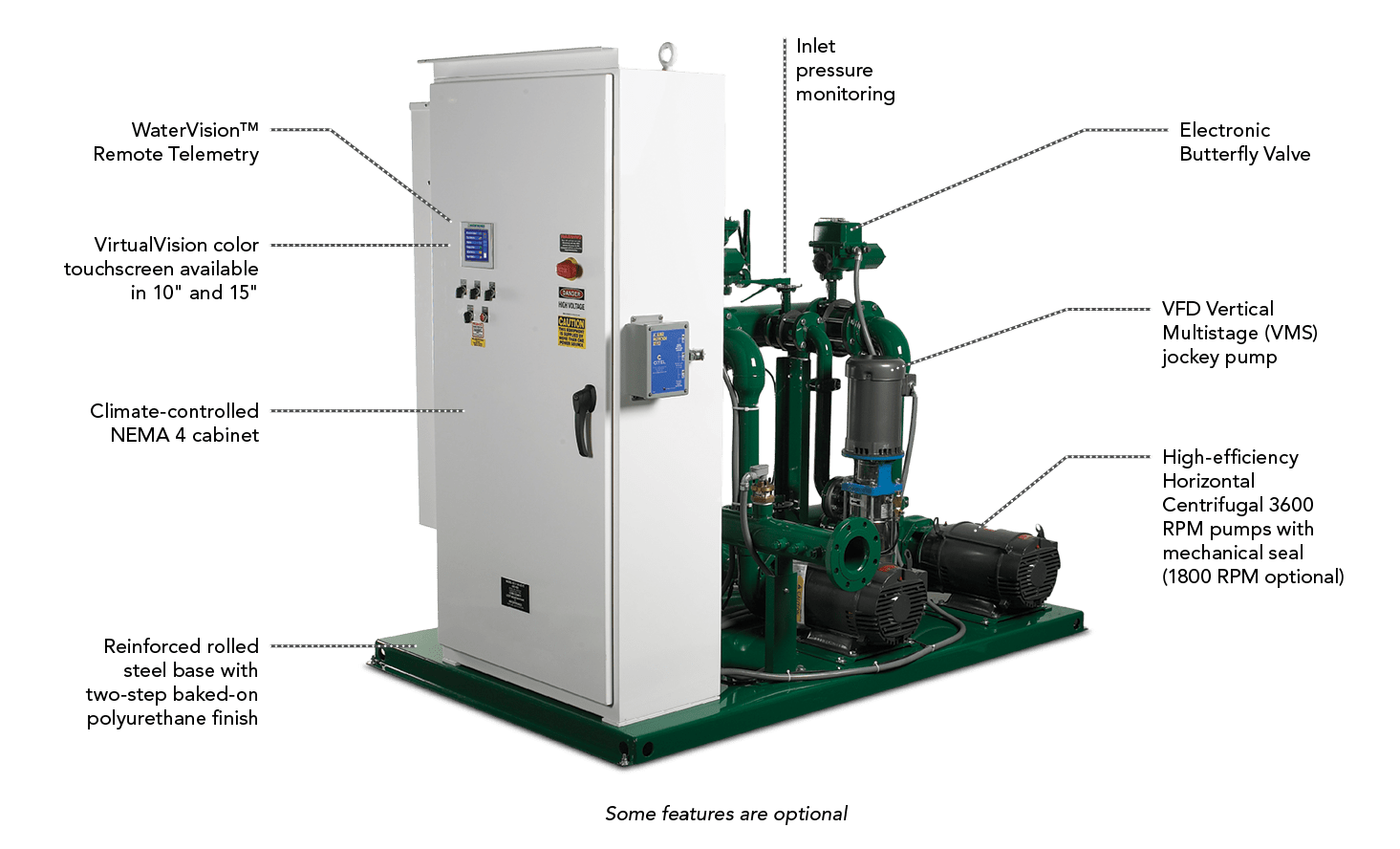

Watertronics - Horizontal Centrifugal (HC) Pumping System for Agriculture

Ideal for pumping from reservoirs, rivers and wells, the Horizontal Centrifugal (HC) system is a single-source solution that can meet a wide range of pressure and flow requirements. Our advanced pump logic uses actual pump curve data to provide intelligent sequencing for optimal wire-to-water efficiency. Engineered for continuous operation in challenging environments, the HC is reliable, rugged, and long-lasting. Modern features like VFD per pump, and cloud-based telemetry increase flexibility and accessibility. Pump stations arrive pre-packaged and factory tested, ready for quick installation and start-up. With proven reliability and pumping efficiency, the HC offers a cost-effective solution and can be fully customized to meet your needs.

- Programmable logic controls which incorporate unique algorithms to optimize pressure regulation and pump pressure characteristics to reduce pressure surges.

- Variable Frequency Drives assure near perfect pressure regulation and incorporate ride-through protection to keep systems operational following loss of power or alarm.

- VirtualVision™ is our easy-to-use touchscreen operator interface with an LCD display for monitoring alarms, changing pump sequencing, adjusting downstream pressure, changing filter flush duration, recording or resetting water usage, calibration, and more.

- Watervision® remote monitoring technology offers user-friendly software to access your pump station from afar.

- Pump-Link® provides real time integration between the irrigation system’s central computer and pump station.

- Unitized skid construction offers a continuous rust-protected sheet of pre-punched steel, free of welding seams or cracks.

- Rust-fighting coatings are individually applied in a process that includes metal preparation, a rust-inhibitive coating, baked epoxy prime coat, and two-part ultraviolet insensitive baked polyurethane finish.

- Inverter Duty Energy Efficient VHS motors available in various voltages.

- End-Suction centrifugal high efficiency pumps.

- Filters designed to resist rust and corrosion and utilize pressure transducers upstream and downstream for superior flushing performance, reliability and accuracy.

- Filter Flush Valve which uses a dirty water tolerant Electric Butterfly Valve rather than a Hydraulic Diaphragm Valve.

- Jockey pumps that eliminate the need to run a larger main pump for applications such as syringing and hand watering.

- Sustain pumps which maintain system pressurization and allow for hand watering.

- Electronic Butterfly Valve (EBV)

- Watervision® Remote Monitoring

- Custom built corrosion-free composite enclosures

- Enclosure heaters and air conditioners

- Enclosure insulation for enhanced sound attenuation

- Sustain and Jockey pumps

- Fertigation equipment and integrated controls

- Premium surge protection

- Choice of station colors (sandstone, green, Custom)

- EZ Feed Injection Systems