HORN Glass Industries AG

- Home

- Companies

- HORN Glass Industries AG

- Products

- HORN GCS - Model Series 1000 - ...

HORN GCS - Model Series 1000 -Distributor

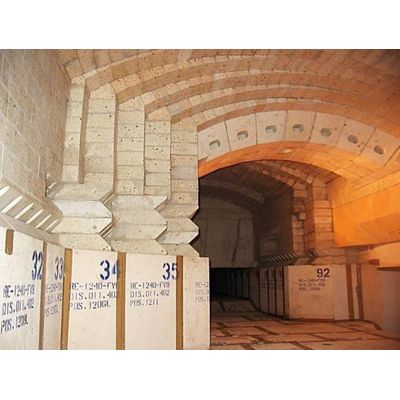

The HORN® distributor design is an up-to-date construction employing all technical requirements.

Most popular related searches

cooling system

air cooling system

level monitoring system

digital temperature controller

open cooling system

instrument housing

level monitoring

automatic monitoring

temperature monitoring

flue gas

DESIGN

- Higher superstructure at the entrance zone – crown execution

- Flat cover blocks at downstream zones

- Optimally calculated distances from the furnace centreline to each forehearth to minimise the risk of glass flow short-circuiting and to optimise the forehearth entrance temperature

- Differentiated control sections for accurate temperature adjustment

- Width individually customised depending on total pull, required temperatures and residence time

- Length individually customised to available space, number and arrangement of forehearths

- Depth individually customised depending on total pull, required temperatures, residence time and glass colour

- Several natural or forced cooling systems are available which are adapted to the design of each distributor:

- Radiation openings

- Direct cooling system (individually adjustable)

STEEL WORK

- Assembly of the forehearths follows conventional design

- Substructure refractories are enclosed in steel casings

- Braced frames support the superstructure

- Designed to meet modern technical requirements to achieve optimal thermal homogeneity combined with minimum energy requirement

- Channel blocks of zircon mullite, fused cast AZS or alumina material

- Forehearth superstructure in sillimanite material and premium insulating refractory materials

- Constant air/gas Ratio

- Safety switch-off system (in accordance with DIN EN 746-2)

- Automatic lambda control (optional)

- Preassembled skids for easy installation including pipework

- Used at distributors and forehearths (GCS® Series 200 and 301-advanced)

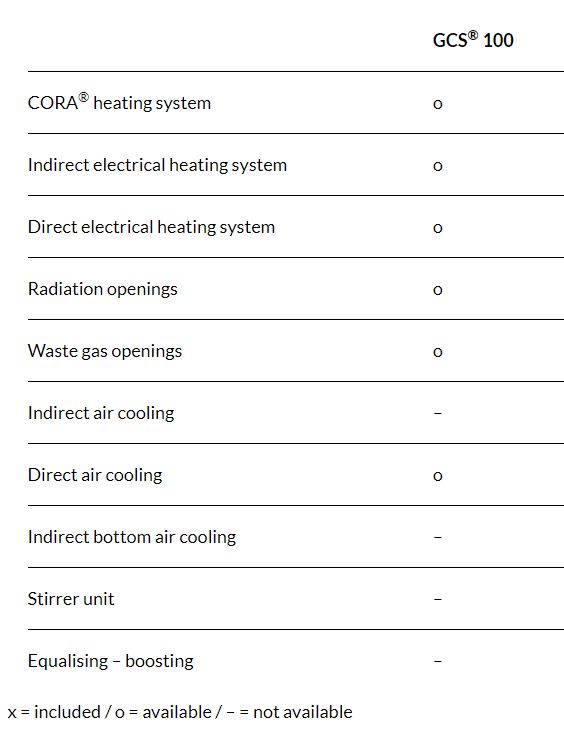

COOLING EQUIPMENT FOR DISTRIBUTORS AND FOREHEARTHS

- Customised cooling fan layout

- Alternatively two central cooling air fans for all air cooling systems, one in operation and one as stand-by

- Radiation and/or flue gas openings can be operated manually or automatically

- Fully automatic temperature control loops in each zone

- Spout heating can be controlled manually or automatically

- Different types of temperature measurements (thermocouples or pyrometers) are available for each zone

- Grid-measurement in equalising zone with K-factor calculation, according to Emhart 9 point formula

- All measuring and control instrumentation housed in a completely assembled and wired control panel

- “Blind” connection possible for the subsequent installation of an additional forehearth

- Opening for the glass level measuring device

- Tailor-made for optimised pre-conditioning of the glass

- Different cooling systems are available and adapted to the specific requirements