HORN Glass Industries AG

- Home

- Companies

- HORN Glass Industries AG

- Products

- HORN GCS - Model Series 200 - ...

HORN GCS - Model Series 200 -Forehearth

This forehearth design is for low and medium capacity and accurate temperature adjustment.

Most popular related searches

air cooling system

digital temperature controller

instrument housing

automatic monitoring

cooling system

temperature monitoring

flue gas

combustion optimization system

automatic monitoring system

laboratory homogenizer

DESIGN

- The superstructure is designed for optimal combustion system performance

- Modular construction system to achieve optimal thermal homogeneity combined with minimum energy output

- Used for up to 50 t/d

- Typical length starts at 10 ft

- Standard width from 16” to 26”

- Standard glass depth of 4” to 6”

- T-type, F-type or Y-type for tandem production available, depending on machinery layout

- Radiation openings are provided in the forehearth superstructure at each cooling zone

- Openings are sized according to the required cooling and are located at the beginning of each zone

- The heat radiation through the opening can be varied by adjusting the damper

STEEL WORK

- Assembly of the forehearths follows conventional design

- Substructure refractories are enclosed in steel casings

- Braced frames support the superstructure

- Designed to meet modern technical requirements to achieve optimal thermal homogeneity combined with minimum energy requirement

- Channel blocks of zircon mullite, fused cast AZS or alumina material

- Forehearth superstructure in sillimanite material and premium insulating refractory materials

- Constant air/gas Ratio

- Safety switch-off system (in accordance with DIN EN 746-2)

- Automatic lambda control (optional)

- Preassembled skids for easy installation including pipework

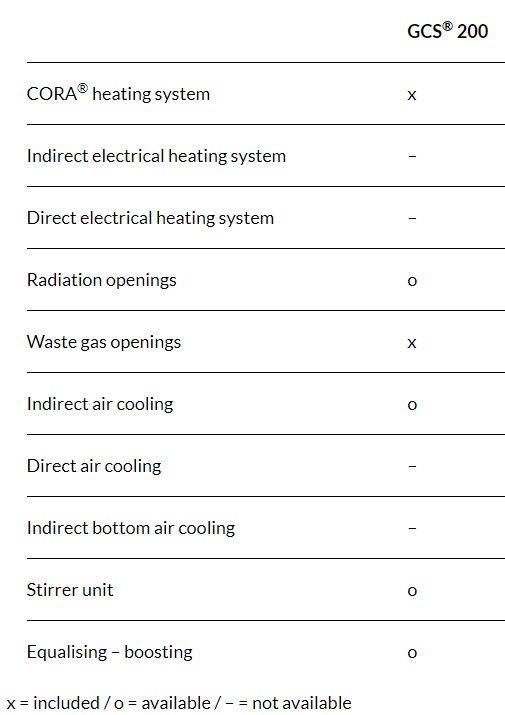

- Used at distributors and forehearths (GCS® Series 200 and 301-advanced)

COOLING EQUIPMENT FOR DISTRIBUTORS AND FOREHEARTHS

- Customised cooling fan layout

- Alternatively two central cooling air fans for all air cooling systems, one in operation and one as stand-by

- Radiation and/or flue gas openings can be operated manually or automatically

- Fully automatic temperature control loops in each zone

- Spout heating can be controlled manually or automatically

- Different types of temperature measurements (thermocouples or pyrometers) are available for each zone

- Grid-measurement in equalising zone with K-factor calculation, according to Emhart 9 point formula

- All measuring and control instrumentation housed in a completely assembled and wired control panel

- Fast and effective cooling with radiation openings

- Refractory can be designed for additional stirrers, VARI-DRAIN® or forehearth boosting