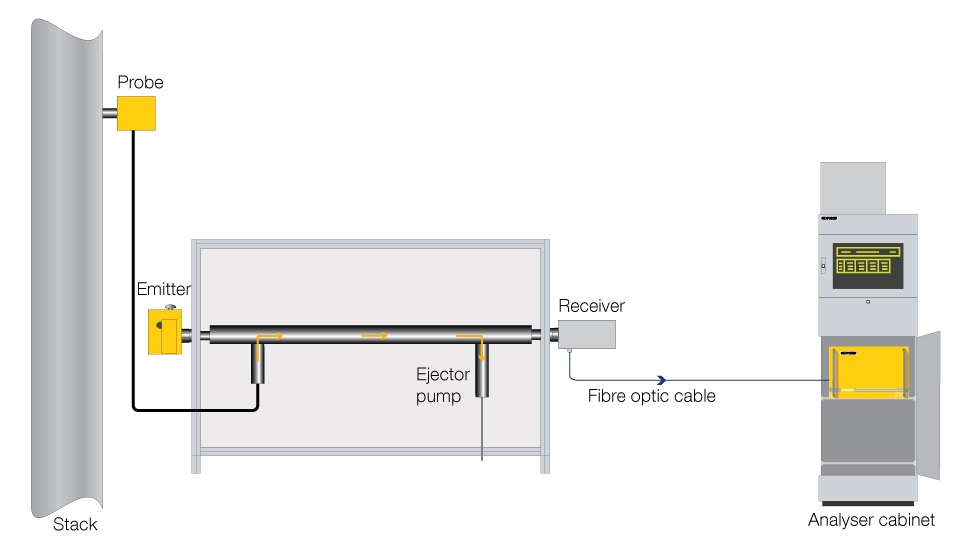

OPSIS - Model 400HWE -Hot Wet Extractive System

A System 400HWE is similar to a System 400FL in that the monitoring path is located in a dedicated measurement cell separated from the gas channel. However, the extraction of the gas from the monitoring point is done with a more traditional sampling unit. This results in a lower gas flow and thus slower gas exchange in the measurement cell but can simplify installation. As with the other system solutions, an AR600 is usually used, and the system can be supplemented with an AR650.

A particular advantage of System 400HWE is that it can be fitted with a gas converter on the inlet to the measurement cell. This enables monitoring of additional types of pollutants, for example:

- total mercury

- H2S in low concentrations

- total reduced sulfur (TRS).

By using two measuring cells with a converter in between, all other types of gases can also be monitored. This provides a very cost-effective monitoring system with low maintenance requirements.

OPSIS DOAS systems have been tested and approved by several international test institutes and national authorities, including the German TÜV and under British MCERTS standards.

Examples of applications where these products can be used:

- Aluminium Smelters

- Waste to Energy Plants

- Cement Industry

- Glass Manufacturing Industries

- Fertilizer Production

- Power Plants

- Mercury Monitoring

- Flue Gas Treatment

- Sulfuric Acid Production

- CO2 Capture

- Chemical Industry

- Ore Refining and Smelting

- Pulp Mills - TRS and H2S Monitoring

- Mineral Wool Production

- Palm Oil Industries

- Steel Industry

- Sulfur Capture at Refineries

- Brick Plants