- Home

- Companies

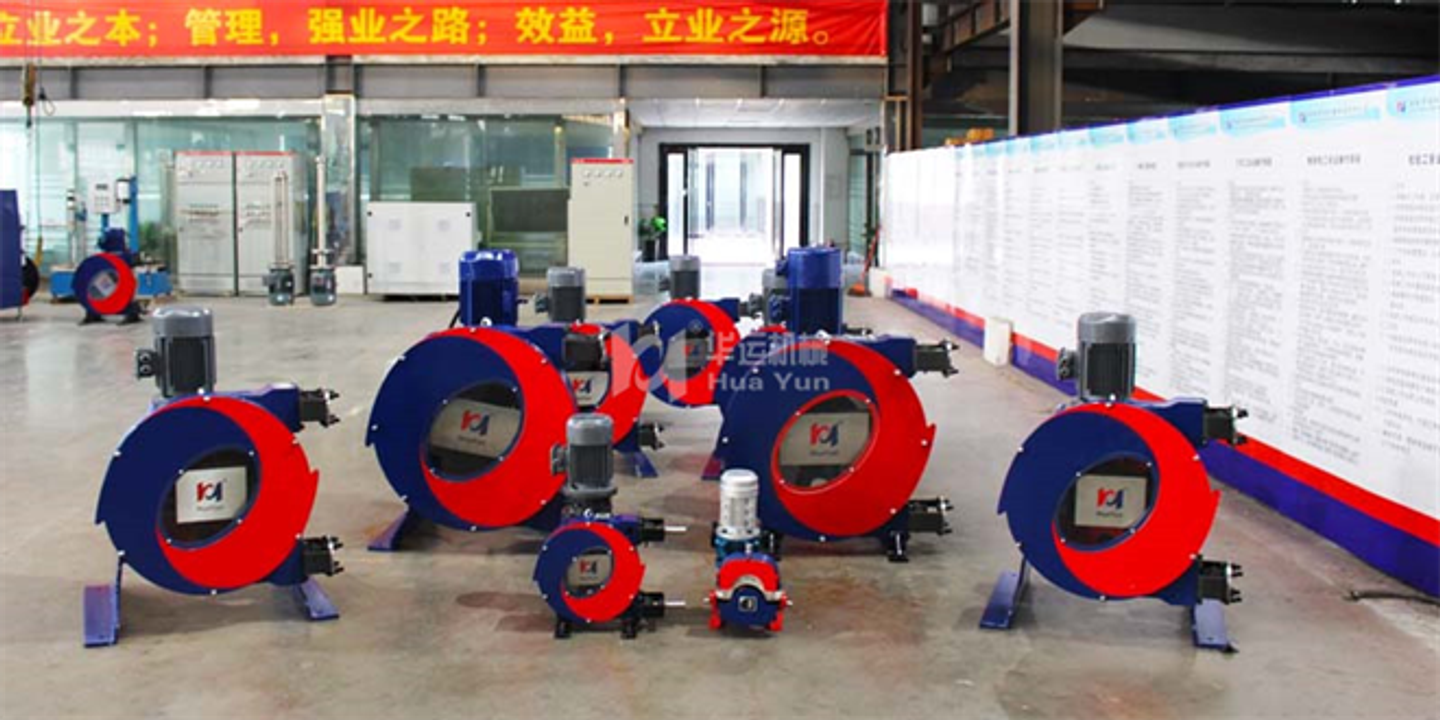

- Hefei Huayun Machinery Manufacturing ...

- Products

- Huayun - Automatic Integration Coating ...

Huayun - Automatic Integration Coating Complete Equipment

Automatic integration coating complete equipment integrates automatic control, automatic feeding, high speed dispersing, recycle grinding, paddle-type mixing, automatic filtering, automatic filling, automatic gland, automatic modulating color, oil mixing and stacking. The system also includes recording parameter regularly, generating management reports, etc. which ensures the paint quality and upgrades the quality level, achieve the closed, constant, high efficient, automatic production.

Feature 1: Fully Closed Production Process

Fully closed production process has been adoptedto the automatic integration coating complete equipment.No leakage of dust pollution and organic solvent, thus it saves the loss of leakage and will not cause the air pollution. Production process is automatic intelligentized. Efficiency and quality are highly improved by monitoring and recording process regularly, adopting computermanagement model.

Feature 2 `.Feeding The Material From The Tank Base

Feeding the material from the base by vacuum pressure makes the short feeding distance and feeding speed quickly.lt avoid backflow and excavation which might happen if dothis job by labor. The material is surrounded by water after entering in the tank, this avoid the powder pollution into the air and blocking at the feeding port. It can feed 500kgs material to the tank within 2 min and keep the performance constantly. Traditional way is to feed material from the top of tank. It SF1 will take 25min to complete the same job, m and the material is easy to adhere to the tank inwall causing the loss of material.

Feature 3: Double Layers Dispersing Disc

The key part of the complete equipment is the disperser and the key part of disperser is dispersing disc. Thus, Dispersing disc is very important to improve the dispersing efficiency. Double layer dispersing disc was adopted high wear-resistance material with high shear capacity and high speed. Efficiency of double dispersing disc is several times more than traditional type.

Feature 4: Fully Closed Manhole

The complete equipment requires transferring with vacuum pressure. If there is leakage point on the tank.the complete equipment will iot work. We install the Sealing silicone on the cover of manhole, this operation avoids the material to contact with manhole cover making he sealing performance much better.

Feature 5: HMU Automatic Production

Microcomputer interface technique and automatic online monitoring are adopted to the production process. Material can be weighed lutomatically and precisely.

Feature 6: Mechanical Sealing With Cooling Water

Traditional way is to use open mixing tank and feed material by labor. This way causes serious dust pollution. We adopts fully closed production process , feed material with vacuum pressure, and install the disperser in the tank, this way avoid dust pollution. High speed disperser is equipped with mechanical sealing with cooling water „ NSK bearings* flexible coupling* etc .which ensures the quality and make it easy to do maintaining job.

Feature 7: High-precisionColor Mixer

The color mixing processcontrolled by computer, avoids the cleaning of huge tanks, saves labor and time, improves :he efficiency and achieves zero release. Automatically select, measure and inject, ligh automation, easy operation and simple naintenance. The packing tank position ;ontrolled by photoelectric sensor, more precise and reliable.

Feature 8: Recoil/bag Filter

Automatically remove the particulate impurities on the surface of the filter element through an efficient mechanical cleaning method, capable of on-line continuous filtration in a single machine, with an accuracy range of 25-3000 um, without producing filter consumables. No need for frequent manual cleaning.

- The straight-line reciprocating type removes impurities directly from the surface of the filler element.

- The shaft seal adopts upper and lower two seals, good sealing effect, the disassembly and replacement are convenient.

- On-line continuous filtration, automatic operation, end the heavy works of filter replacement and cleaning.

- Less the filter pressure loss, flow is stable, reducing pipeline energy consumption, conducive to continuous and stable process.

- Closed filter to prevent leakage of dangerous materials, which is conducive to the safe production.