- Home

- Companies

- Brentwood Industries, Inc.

- Products

- Brentwood ShockWave - Hybrid-Fluted ...

Brentwood ShockWave - Hybrid-Fluted Fills

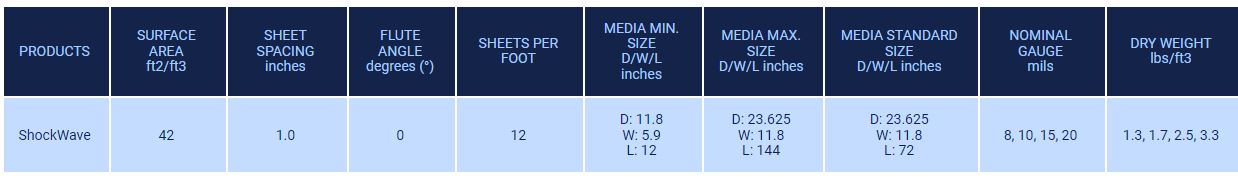

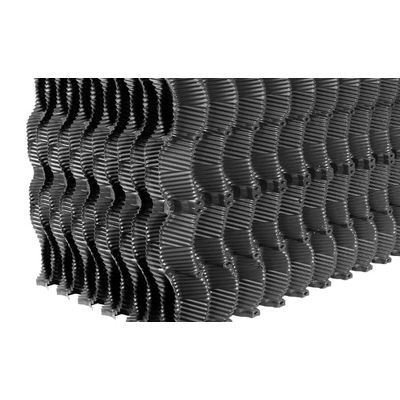

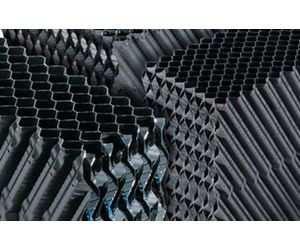

ShockWave is a thermally engineered advancement to standard vertical-fluted products. Its enhanced vertical flute orientation and patented PowerCurve™ design leverage the fouling resistance of vertical-fluted products with the thermal performance of high-efficiency fills. Brentwood has improved the use of the sheet surface area and incorporated diamond tube channels that provide a clear vertical sight path through the product. These design features promote mixing of the air as it moves through the pack, maximizing evaporative heat transfer and exceeding the performance of cross-fluted fills while incorporating the fouling resistance of vertical-fluted products.

- Designed for applications with compromised water, such as power plants, refineries, and steel mills

- Engineered without flute crossovers to increase fouling resistance

- Available Mechanically Assembled or solvent welded

Fouling Resistant

Brentwood`s low-fouling fills have been designed to provide a solution for applications with poor water quality, preventing the media from plugging and improving overall tower efficiency.

Shockwave balances high efficiency with fouling resistance to improve heat transfer and maximize tower performance.

Brentwood`s Mechanical Assembly technology has been improved for the production of Shockwave, yielding connections that are 50% stronger than glued.