- Home

- Companies

- Okada America, Inc

- Products

- Okada - Model TOP21LT-150 FT-LBS Class ...

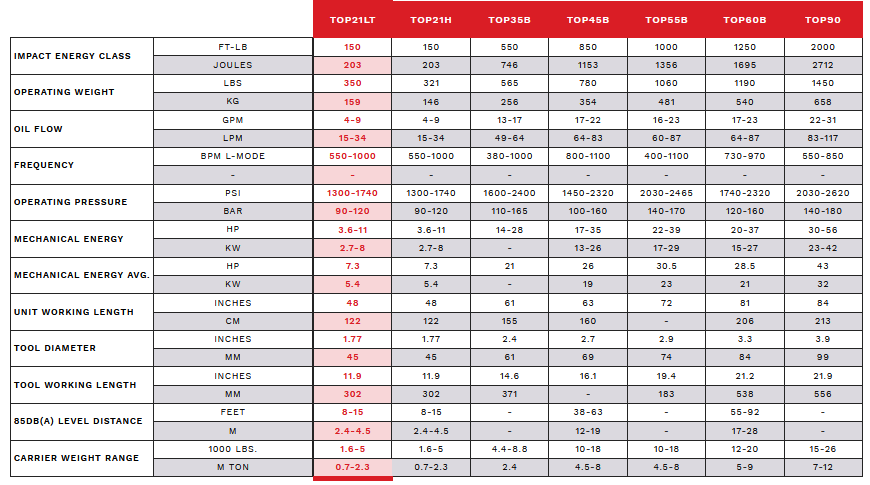

Okada - Model TOP21LT-150 FT-LBS Class -Hydraulic Breaker

Advanced OKADA technology eliminates the need for an accumulator without affecting the hydraulic apparatus on the carrier machine, reducing both maintenance costs and downtime.

Precision machining processes and strict Okada quality control are used to produce all main breaker components. There is no need for complete assembly replacements and the use of high precision parts equate to economical, labor-saving rebuilds of your Okada breaker.

- Simple, proven internal breaker design and side plates are used, making the Okada breaker more cost effective, reducing maintenance time & costs and delivering greater operation uptime!

- With scheduled routine maintenance & proper lubrication 4,000-6,000 hours of operation can be achieved without replacing major components

- Lower overall operating costs & TCO

Seals

Cup seals are utilized to secure the flow in the oil and gas chambers.

Nitrogen gas

Cushions piston on the upstroke, eliminating the need for shock absorbers. Increases the piston down stroke force.

Working tools

Choice of moil, chisel, blunt and special application tools.

Piston Travel/Long Stroke Design

Travels through one machined piece (no misalignment). The long stroke design reduces shock loads and vibration, which can cause operator fatigue and machine stress. Okada breakers have the highest tolerance to high operational back pressures available without negative operational effects.