- Home

- Companies

- Vaughan Company, Inc.

- Products

- Vaughan - Model Rotamix - Hydraulic ...

Vaughan - Model Rotamix -Hydraulic Mixing System

The Vaughan Company Rotamix system is exactly what it claims to be — the best mixing system available today. The Rotamix system keeps your operations running smoothly with American-made durability and low life cycle costs.

- Guaranteed performance

- Includes 10-Year full Nozzle Warranty

- Improves volatile solids reduction

- Increases gas production

- Reduces sludge volume

- Saves energy during non-peak hours

- Backed by field-experienced experts

- No moving parts within the tank

- Allows continued mixing until tank is empty

- Allows use of single mix pump for multiple tanks and transfer

- Prevents clogging with the Vaughan® chopper pump

- Costs less to purchase, install and operate

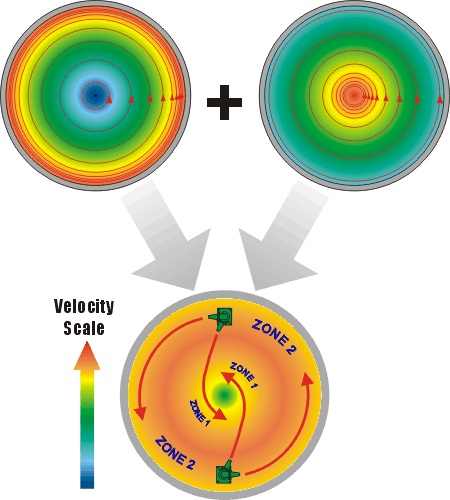

The Rotamix system incorporates several basic principles of physics and hydraulics, including uniform and vortical fields of flow, induced flow and surface contact. Combined together, this unique mixing system optimizes solids contact due to the homogeneous state.

Dual-Zone Mixing

The Rotamix dual-zone mixing pattern is a combination of both uniform and vortical fields of flow. In a uniform field of flow, the entire contents rotates as a solid unit with the highest velocity at the outside. In a vortical field of flow, fluid velocities are the greatest at the center, thus creating a vertical-axis vortex. The Rotamix system combines both uniform rotation (ZONE 2), and a vertical-axis vortex (ZONE 1), creating unique dual-rotational zones.

High Velocities

With dual-zone mixing, average velocities are higher and steadier. Solids are also prevented from settling in the center.

Induced Flow

High velocity nozzles also increase the effective mixing volume by inducing entrained fluid, thus significantly increasing the overall mixing effect. High velocity nozzles induce flow over a long distance, thus generating an overall effect over a large volume.

Surface Contact

The Vaughan® Chopper Pump not only eliminates nozzle clogging, but also optimizes surface contact by constantly reducing solids size, thus increasing total surface area.

- Anaerobic Digesters

- Egg-Shaped Digesters

- Sludge Storage Tanks

- Sludge Blending Tanks

- Influent Channels

- Equalization Tanks

- Secondary Digesters

- Aerobic Digesters w/ Aeration

- Alum Sludge

- Lime Slurry Storage

- Lime Stabilization

- Anoxic Zone Mixing

- Septage Waste Haulers

- CSO Tunnels

- CSO Retention Basins

- Ground Storage Tanks

- Recycled Food Wastes

- Textile Waste

- Liquid Fertilizer

- Pulp & Paper Black Liquor

- Refinery Waste Containment

- Mining Fine Solids Suspension

Cost Savings

When compared to conventional mixing systems, the Rotamix system can save up to 60% in combined capital, operation and maintenance costs.

Complete Mixing

Multiple nozzles allow effective mixing energy distribution, eliminating the need for rotating nozzles. By using the Vaughan chopper pump, surface area and subsequent organic breakdown is maximized.

Energy

- Ability to intermittently mix tanks after long periods of storage, offering power savings

- Allows intermittent operation of conventional process systems, reducing energy costs

Operation

- Fixed dual rotational pattern makes rotating nozzle designs obsolete

- Vaughan Chopper pumps virtually eliminate problems with fibrous material and

- other debris, while ensuring pumps remain clog-free

- Efficient mixing optimizes chemical consumption in sludge dewatering applications

- Operates without liquid level dependency

- Meets or exceeds high rate digester designs

Minimal Maintenance

- No scheduled nozzle assembly maintenance required

- No rotating equipment within the process

- Reduces confined space entry into tanks for maintenance

Capital

- Ability to mix multiple tanks, using only one pump

- Ability to fill, mix and transfer using only one pump

- No access walkways, platforms or hoists required

- Complete installed Rotamix system typically costs less than equipment alone for other types of mixing systems

- Potentially reduces cost of aeration equipment

- Easily retrofits into existing tanks

- Ability to work with flat floor design reduces construction costs

The Rotamix System Nozzle Assemblies

The Rotamix system uses fixed nozzle assemblies. Once the nozzle assembly is installed, the nozzles are adjusted to the factory specified angle, and permanently tightened. No additional adjustment is required.

Nozzle assemblies are offered in single and double nozzle (patent pending) configurations, depending on tank diameter and depth. All fittings are ductile cast iron and glass-lined for abrasion resistance, reduced friction, and to eliminate Struvite adhesion. The tapered nozzle barrels are 1-inch thickness for long-term wear protection. The entire assembly is white metal sandblasted, and then powder coated with 3M TM Scotchkote TM Fusion Bonded Epoxy Coating, a one-part, heat-curable, thermosetting epoxy coating for superior surface protection. Each nozzle assembly includes a 10-year full warranty.

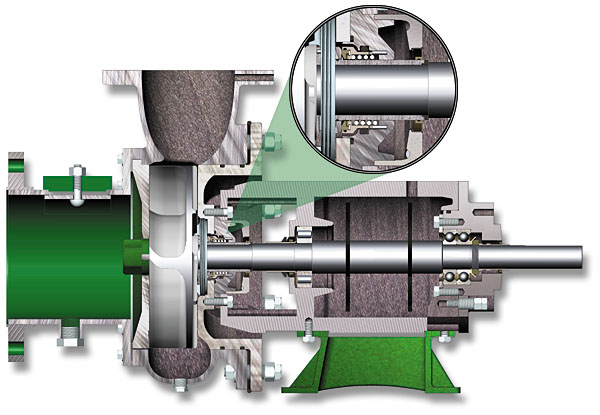

The Vaughan® Chopper Pump

Vaughan`s chopper pump is the heart of the Rotamix system. Vaughan’s proven technology over the past 45 years provides long-term low maintenance, and the highest reliability of any chopper pump. Continuously chopped solids not only eliminate nozzle clogging, but enhance sludge quality. Digester efficiency is increased by further reducing solids size and increasing surface contact. Vaughan’s unique features necessary to provide this reliability include:

- Patented chopping design eliminates nozzle clogging

- Wear parts heat treated to 60+ Rockwell C Hardness extends pump life

- Oversized shafting and bearings extends pump life

- Heavy duty "flushless" mechanical seal (other seal designs available) assures leak-free operation

- Back pull-out design allows adjustment of all cutting clearances without disconnecting suction or discharge piping

Other configurations available include vertical dry pit, submersible, self-priming, vertical wet well, and recirculating pumps. All Vaughan pumps include a written Performance Guarantee, your assurance of clog-free pump operation.