- Home

- Companies

- Poly Processing Company

- Products

- Poly Processing - Hydrochloric Acid ...

Poly Processing - Hydrochloric Acid (HCL) for Chemical Storage

Controlling a chemical - and its fumes. Also known as muriatic acid, hydrochloric acid is used to acidize petroleum wells, remove scales from boilers, aid in ore reduction and serve as a chemical intermediate, among other applications.

This pungent liquid is a strong, highly corrosive acid, and it presents serious storage challenges:

- Hydrochloric acid has an extremely low pH, making it highly corrosive.

- The chemical creates toxic fumes that can deteriorate equipment – and these fumes can be fatal to employees. To control the chemical’s fumes, the tank’s venting system must be exact.

- Tank maintenance can also be an issue because of fuming. Entering the tank must be avoided at all costs, and part replacement must be minimized.

By creating a strong, corrosion-resistant tank system that ties into a scrubber system, all of these issues can be addressed.

IMFO® construction eliminates the need to enter the tank for cleaning, helping employees avoid HCl’s toxic fumes.

High-density crosslinked polyethylene (XLPE) ensures the strength of the tank.

Tank

IMFO® Vertical Flat Bottom:

- 200–13,650 gallons

- 1.9 spg rating

Non-IMFO® alternative:

Standard Vertical Flat Bottom:

- 30–13,650 gallons

- 1.9 spg rating

SAFE-Tank® Double Wall Tank:

- 55–8,700 gallons

- 1.9 spg rating for primary tank

- Spg ratings for secondary tanks ≥ 3,000 gallons may be equal to or 1 less spg than primary tank.

- All other tank sizes must equal primary tank spg rating.

Secondary containment

Recommend SAFE-Tank® secondary XLPE as shown above

Non-SAFE-Tank® Alternatives:

- PPC secondary containment basin

- Other secondary containment suitable for hydrochloric acid, of adequate size for use

Fittings

Sidewall: Recommend 3? maximum B.O.S.S. fitting®

Dome: No restrictions

Plumbing to the tank

- Required use of flexible connections with fittings on lower third of sidewall

- Allows for lateral and vertical expansion and contraction of the tank

- Reduces pump and piping vibration stress on the tank

- Expansion joints must meet the following minimum requirements:

- Axial Compression ≥ .67?

- Axial Extension ≥ 0.67?

- Lateral Deflection ≥ 0.51

- Angular Deflection ≥ 14°

- Torsional Rotation ≥ 4°

Venting

Foundation and restraints

- PPC IMFO® tank pad or smooth concrete, asphalt or steel foundation designed to accommodate IMFO®, SAFE-Tank® or vertical tank

- No restraint or ladder attachment bands circumscribing the tank are allowed. Cable restraint systems must pass cables over the top of the tank.

Temperature

Product should not exceed 100°F at delivery or during storage to maintain ASTM D1998 design parameters.

Lid

Fume-tight manway cover to manage release of chemical gases

Options

Restraint systems for wind and seismic, level gauges, ladders, heating pads, insulation and engineering stamp

Note

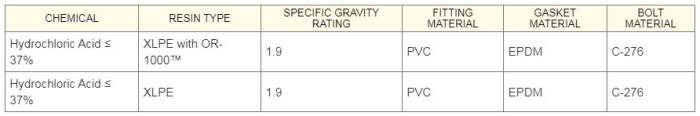

XLPE with OR-1000™ = 5 Year Warranty

XLPE = 3 Year Warranty