- Home

- Companies

- Poly Processing Company

- Products

- Poly Processing - Hydrofluoric Acid ...

Poly Processing - Hydrofluoric Acid (HF) for Chemical Storage

Reducing the risk of human exposure: Used in the production of aluminum, fluorocarbons and gasoline and for applications like glass etching and uranium processing, hydrofluoric acid is an extremely dangerous chemical that must be handled with the utmost care.

- This corrosive liquid penetrates tissue more quickly than typical acids. Toxicity can occur through dermal, ocular, inhalation and oral routes.

- Since HF alters nerve function, accidental exposure can go unnoticed by the victim, delaying treatment and increasing the extent of injury.

- It can also be absorbed by the blood through the skin, reacting with blood calcium and potentially causing a heart attack.

The extreme nature of this chemical calls for superior structural integrity – the level of integrity Poly Processing is known for.

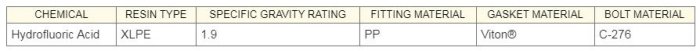

When people’s lives are at risk, you can take no chances. You need a system that goes above and beyond to prevent contact with this corrosive acid. That system starts with a crosslinked polyethylene tank. XLPE is a thermoset resin that gives customers 20 times the environmental stress-crack resistance, 10 times the molecular weight and 5 times the impact and tensile strength of HDPE. This system carries a warranty for a full five years.

A SAFE-Tank can help reduce health and environmental concerns due to closed containment of hydrofluoric acid.

If a SAFE-Tank is not a possibility, an IMFO flange can be used to reduce hands-on maintenance, thereby reducing the risk to your employees.

For additional information on storing hydrofluoric acid, including recommended storage tanks and components, download our Hydrofluoric Acid Guide below. Or, download the Tank Designs & Specifications Guide to see all of our chemical storage products.

Tank options include:

High-density crosslinked polyethylene (XLPE) construction for maximum strength

OR-1000™ antioxidant inner surface

Integrally Molded Flanged Outlet (IMFO®) for complete drainage

SAFE-Tank® design for “tank-within-a-tank” protection

IMFO® Vertical Flat Bottom of XLPE:

- 230–13,650 gallons

- 1.9 spg rating

Non -IMFO® alternatives :

SAFE-Tank® XLPE:

- 55–8,700 gallons

- 1.9 spg rating for primary tank

- Spg ratings for secondary tanks ≥ 3,000 gallons may be equal to or 1 less spg than primary tank.

- All other tank sizes must equal primary tank spg rating.

Standard Vertical Flat Bottom XLPE:

- 30–13,650 gallons

Alternative secondary containment: PPC secondary containment basin or other secondary containment suitable for hydrofluoric acid, of adequate size for use

Plumbing: Requires use of flexible connections with fittings on lower third of sidewall. See Fittings & Accessories for flexible connections options.

- Expansion joints must meet the following minimum requirements:

- Axial Compression ≥ .67?

- Axial Extension ≥ 0.67?

- Lateral Deflection ≥ 0.51

- Angular Deflection ≥ 14°

- Torsional Rotation ≥ 4°

Venting: See Venting Chart

Foundation: PPC IMFO® tank pad or smooth concrete, asphalt or steel foundation designed to accommodate IMFO®, SAFE-Tank® or vertical tank

Temperature: Product should not exceed 100°F at delivery or during storage to maintain ASTM D1998 design parameters.

Lid: Fume-tight manway cover to manage release of chemical gases

Options: Restraint systems for wind and seismic, level gauges, ladders, heating pads, insulation, mixer mounts and engineering stamp