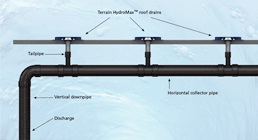

Hydromax Siphonic Drainage System

The Terrain HydroMax Siphonic Drainage System effectively ‘sucks’ water from the roof area for faster, more efficient capture and removal.

Changing rainfall patterns due to climate change are leading to increased frequency of intense rainfall with extreme weather events predicted to be become more common place.

The need to accommodate this in current building design can challenge traditional methods of roof drainage, with requirements to ensure efficient removal of rainwater from roof areas. Terrain HydroMax Siphonic Drainage is a complete and proven system, designed to rapidly remove high volumes of water, typically from large roof areas.

The Terrain HydroMax system `sucks` water from the roof, using a powerful hydraulic force created by water accelerating down the full height of the building to deliver far greater capacity and flow rates than a gravity system.

In a gravity drainage system, pipework carries both air and water. The flow in gravity pipes is extremely inefficient because of the large core of air which enables the water to flow resulting in the need for larger pipes and more of them as well as extensive underground systems.

In the Terrain HydroMax system as rain falls, the roof drain prevents the ingress of air, rapidly purging it until the system is fully primed and running full bore. Water is transported in smaller diameter pipes to fewer, more convenient locations.

The system responds quickly to rainfall changes, is self-cleaning, drains rapidly when rainfall ceases, and is designed to prevent blockage by leaves, twigs and other debris.

Features of Terrain Siphonic system

With ten times the flow capacity of a conventional gravity system and significantly faster water removal rates, Terrain HydroMax `sucks` excess water from a roof to cope with downpours that would overwhelm a gravity system and is ideal for complex roof shapes.