- Home

- Companies

- Henan Greatwall Machinery Co., Ltd.

- Products

- Greatwall - Model PF - Impact Crusher

Greatwall - Model PF -Impact Crusher

The impact crusher is a new type of crushing equipment, developed and designed by Great Wall Machinery based on customers’ feedback and years of production experience, attracting domestic and foreign advanced technologies and combining with the specific conditions of the domestic sand and gravel industry. The finished product is cubic, free of tension and cracks, and has a very good grain shape.

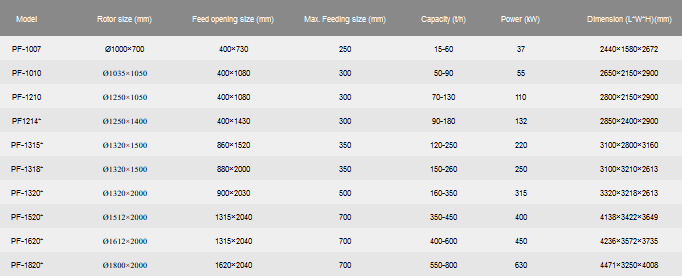

- Processing Capacity: 15-800TPH

- Max. Feeding Size:250-700mm

- Application Fields: Mining, metallurgy, construction, highway, railroad, water conservancy, cement industry, and ore processing, etc.

- Applied Materials: Limestone, dolomite, concrete, gypsum, basalt, construction waste, etc.

- Customized Service:Small, medium, and large models can be customized, to meet customers’ demands.

Impact crushers can crush various coarse and medium materials with a particle size of not more than 200-700mm and a compressive strength of not more than 350MPa, such as limestone, concrete, dolomite, construction waste, etc. The size of the discharge granularity can be adjusted, and the crushing specifications are diversified.

The impact crusher is widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical, and other industries for medium and fine crushing materials. The size of the discharge particle size can be adjusted, and the crushing specifications are diversified. The finished product is cubic, free of tension and cracks, and has a very good grain shape.

It is crusher equipmentthat is of finer size than the jaw crusher.

It is usually matched with a jaw crusher in the complete crushing production plant.

- Big feeding mouth, high crushing chamber, high adaptability of the material hardness, and a small portion of powders

- Very convenient to adjust the gap between the impacting plate and the plate hammer, so it can effectively control the discharging granularity

- Final product is the cubic shape

- Compact structure and strong rigidness, and the rotor has big rotational inertia

- With a high chromium plate, it has shock resistance, abrasion resistance, and a big impacting force.

- Easy to make maintenance, very economical, and reliable.

An impact crusher is a crushing machine that uses impact energy to crush materials. When it is working, the motor drives the rotor to rotate at a high speed, on which the blow bar is assembled. As soon as the materials get into the working area of the blow bar, they will be stroked by the blow bar and thrown to the impact devices around the rotor. The high-speed forces the material to rebound from the impact liner to the area where the blow bar affects until they have been crushed to the qualified size. The clearance between the impact rack and the rotor can be adjusted, to change the size and shape of the output products.