Eltech Electrodesigns and Energy Systems Pvt. Ltd.

- Home

- Companies

- Eltech Electrodesigns and Energy ...

- Products

- Induction Melting

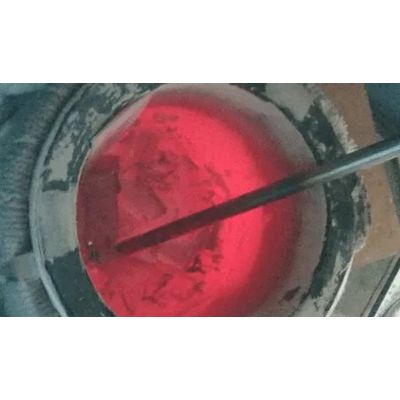

Induction Melting

ELTECH Induction Melting Furnace is designed for maximum electrical efficiency.Our furnaceis designed for each customer’s specific melting application, providing close temperature control and maximum efficiency. Furnaces can be designed for various purposes such as melting iron and steel, precious metals, ferrous and nonferrous metals; refining of high purity metal and alloys; smelting; and vacuum and controlled atmosphere melting.You can find the simple comparison between electric coil heating and Induction heating which itself makes much difference.

Most popular related searches

aluminium melting furnace

gold melting furnace

metal melting furnace

digital temperature controller

non-ferrous metal

carbon emissions

furnace

vacuum sensor controller

crucible

carbon reduction

- Saving in process time, energy used, environment and manpower

- Automated systems having temperature accuracy of +/- 1% of the set temperature

- Uniform heating achieved while maintaining higher temperature accuracy

- Moisture-less heating resulting in increased crucible life and product quality

- Compact dimensions resulting in space saving and people friendly operations

- Easy maintenance and service available locally

- Reduction in carbon emission due to the elimination of fossil fuels

- Substantial reduction in shop-floor temperature

- Ferrous metals melting furnace (Steel, Cast Iron)

- Aluminium melting furnace

- Copper melting furnace

- Zinc melting furnace

- Gold melting furnace