- Home

- Companies

- Dripping Wet Water, Inc.

- Products

- CLO2IX - Industrial Chlorine Dioxide ...

CLO2IX - Industrial Chlorine Dioxide System

The CLO2IX Industrial System is the ultimate Chlorine Dioxide generator system. Built to withstand harsh and humid industrial water treatment conditions, the system consistently produces a pure solution of Chlorine Dioxide by utilizing the Dripping Wet Water patented Chlorine Dioxide production method.

- 0.25 lb/day to 200 lb/day Standard Systems

- No ClO2 Storage Required – Not a Batch Process

- Dilute ClO2 Solution Produced – Inherently Safe

- Self-Monitoring and Self-Correcting Operation

- Industry-Proven, Reliable Components

- Reverse Osmosis Membrane Systems

- Open Cooling Systems

- Closed Cooling Systems

- Secondary Disinfection

- Odor Control

- Iron & Manganese Removal

Chlorine Dioxide is the ultimate biocide. As a dissolved gas in solution, it can destroy and remove biofilm, eliminate both sessile and planktonic bacteria, and prevent their regrowth without interfering with most water treatment chemistry. As a weak oxidizer, it can destroy odors, clarify, and precipitate iron and manganese from contaminated water sources. As the ultimate biocide, it can eradicate Legionella and other harmful bacteria living and growing in water systems. These properties make Chlorine Dioxide the ideal biocide for most industrial water treatment applications.

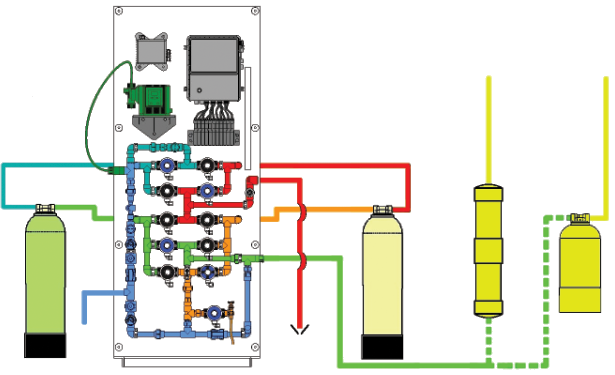

The CLO2IX Industrial System is based on pure water technology found routinely in the pharmaceutical and semiconductor industries where purity and safety are not optional. Instead of the traditional way of making Chlorine Dioxide by either mixing concentrated chemicals or through electrochemistry, which produces dangerous byproducts, the CLO2IX method combines ion exchange and catalytic technologies to ensure consistent product quality in a rugged industrial piece of equipment.

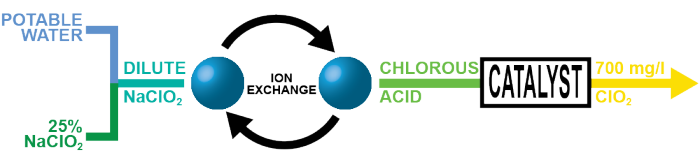

- Inlet Potable Water - A potable water source is required for the system.

- Sodium Chlorite - A 25% NaClO2 solution is diluted with potable water, such that the resulting concentration of NaClO2 is 1,250 mg/l.

- Chlorous Acid - The dilute NaClO2 flows through the ion exchange vessels, where the NaClO2 is converted to HClO2 through the exchange of the Na+ in solution for the H+ on the cation resin.

- Chlorine Dioxide - The HClO2 is converted to dilute ClO2 in the catalyst cartridge. The concentration of solution is a safe 700 mg/l.

- Regeneration - The H+ ion in the regenerant acid forces the Na+ ion off the exhausted cation resin. The system is a duplex system, which means that when one cation resin vessel is converting NaClO2 to HClO2 the other vessel is in regeneration. When the system determines that the first vessel is exhausted, the system automatically switches sides so that HClO2 production is not interrupted. To increase efficiency, the Impulse Regeneration Method is utilized.

- Drain - The waste regenerant containing the Na+ ions is flushed to drain as part of the regeneration process. The system also primes itself to drain.