- Home

- Companies

- SnowPure Water Technologies

- Products

- SnowPure Electropure - Model XL-R ...

SnowPure Electropure - Model XL-R Series -Industrial, Electronics Electrodeionization (EDI) Modules

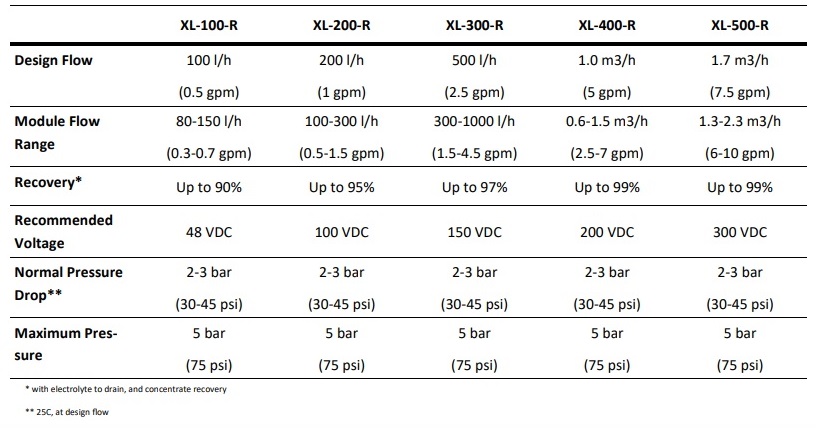

XL-R Electropure EDI products can handle a range of flows from 50 l/h to 2.3 m3/hr (10 gpm), depending on the specific requirements of the customer. These are designed for rugged industrial EDI systems, whether made from PP or PVC or Stainless Steel.

ELECTROPURE™ XL-R modules are industrial EDI modules for producing highresistivity Ultrapure water. They are configured to easily retrofit existing systems with added Electropure™ technology benefits, so the old troublesome Dow Omexell® and GE E-Cell® CONCENTRATE RECIRCULATION IS ELIMINATED. ELECTROPURE™ XL-R modules have the compact Electropure profile and have Electropure™ EDI technology inside. This includes Electropure’s patented Excellion™ membranes, our unique non-scaling electrode system, and our efficient thin-cell technology.

And with Electropure™ EDI thin-concentrate technology, there is no need for the troublesome Omexell® and E-Cell® recirculation system, so it can be eliminated from the system. With the mass-transfer built into Electropure™ EDI thin-concentrate technology, you don`t need either salt injection or feed-and-bleed systems. You also don`t need the IONPURE® “all-filled” design.

XL-R Industrial, Electronics EDI

- XL-100-R

- XL-200-R

- XL-300-R

- XL-400-R

- XL-500-R

- Feed and product ports are 1-inch female pipe thread (FNPT).

- Simple systems can be built with multiple modules in parallel.

- The -R series is an improved design with the bolt heads on the opposite face.

- No concentrate recirculation or brine injection

- Thin-Cell efficient technology

- Thin-Concentrate non-scaling technology

- Unique non-scaling electrode system

- Patented Excellion™ membranes

- Electropure™ EDI technology was born in 1977,

- before Ionpure

- SnowPure is privately held

- SnowPure is your partner, not a competitor. “We Don’t Compete with our Customers.”

- High quality Electropure™ EDI training and OEM support

- Continuous Process-no upsets

- Operating cost is minimized

- No hazardous waste, no associated costs and risks

- No regeneration acid or caustic

- Flexible—easy to expand a modular EDI system

- Reliable—no recirculation system components to fail

- SnowPure believes strongly in training—this helps ensure field success with Electropure™ EDI systems.

- SnowPure assists new OEM customers through their system design phase.

- Our customers also have access to our Best Practices P&IDs to aid in their EDI system optimization.

- Combined with ongoing Technical Service, we help ensure success.