- Home

- Companies

- Pingxiang Zhongci Environmental ...

- Products

- Zhongci - Industrial High Alumina ...

Zhongci - Industrial High Alumina Ceramic Grinding Media Balls

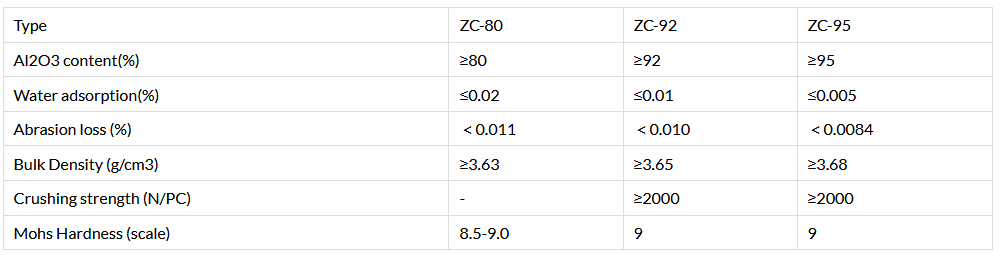

The microcrystalline wear-resistant 80% alumina ball produced by Zhongci ceramic materials have good performance in grinding Feldspar, Clay etc, is a high-quality grinding medium made of selected high grade material, advanced molding technology and calcined in high temperature tunnel kiln. Possessed with high density, high hardness, low wear, good seismic stability and good corrosion resistance, the products are the most ideal medium for grinding glaze, blank and mineral powder processing, and are used as the grinding medium of ball mill in ceramics, cement, paint, refractory, inorganic mineral powder and other industries.

80% Alumina grinding ball is one ideal mill grinding media, it can keep the purity and improve the stability of the grinding materials especially the ceramic glaze. High alumina ceramic balls as grinding ball with high quality raw materials as well as the middle alumina ceramic balls are produced with the following technology: advanced spray drying technology, dry type full automatic isostatic pressure and high temperature roller kiln sintering technology.

Size of 80% Alumina Ceramic Balls:

- Normal size: 20mm, 25mm, 30mm, 40mm, 50mm, 60mm. 70mm These sizes our factory produce regularly, many of them are in large stock.

- We can provide the other sizes by customers` requirements, just tell us what you need.

High Alumina Grinding Ball, is higher than the common alumina balls. When it is working, the ball won`t pollute the grinding materials, so it can keep the purity and improve the stability of grinding materials especially the ceramic glaze 92% Alumina Grinding Ball, Due to its excellent properties such as high strength, high hardness, high wear resistance, high specificity, small size, high temperature resistance, corrosion resistance, and no pollution, alumina grinding balls are widely used in various ceramics, enamels, glass, chemical and other factories. Finishing and deep processing of rough and hard materials, as the grinding body of fine grinding equipment such as ball mills, pot mills, and vibration mills. 95% High Alumina Grinding Ball have the advantages of high density, high hardness, high wear resistance, etc., and are widely used in ceramic factories, cement factories, enamel factories, glass factories and other ball mills as grinding media for ceramic raw materials and glazes. During the grinding/grinding process, the ceramic balls do not break and contaminate the abrasive material.