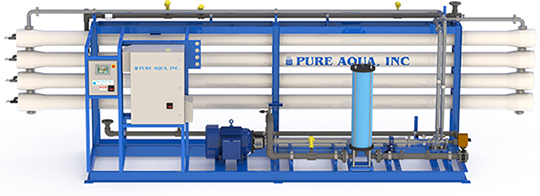

Pure Aqua - Model SWI -Industrial Seawater Reverse Osmosis Desalination Systems

For continuous or heavy-duty service in marine applications on and off shore, Pure Aqua manufactures a full line of designed seawater desalination systems.

Seawater Reverse Osmosis

Seawater Reverse Osmosis (SWRO) is a reverse osmosis desalination membrane process that has been commercially used since the early 1970s. The typical single pass SWRO system consists of the following components:

-

Intake: well or open water

-

Pre-treatment: Filtration and chemical dosing

-

High-pressure pump: to achieve the needed pressure

-

Membrane assembly: to perform the desalination process

-

pH adjustment: to adjust the alkalinity or acid level

-

Disinfection: to prevent any bacterial or organic growth

Pure Aqua, Inc. has manufactured and supplied hundreds of commercial and industrial seawater reverse osmosis systems with feed water TDS up to 45,000 ppm.

Customizable RO System Capacity

Our SWI Series is available with capacities ranging from 8,000 GPD to 660,000 GPD and a maximum feed water TDS of 42,000 ppm. We offer standard SWI Series units as well as customizable to fit you water application needs. From your five star resort to the world`s largest desalination plant in the United Arab Emirates, Pure Aqua is ready and able to provide only the best in industrial desalination systems.

Pure Aqua’s Sea Water Reverse Osmosis Systems are capable of removing salts as well as other impurities such as bacteria, sugars, proteins, dyes and constituents that have a molecular weight greater than 150-250 Dalton. Pure Aqua supplies a full line of standard and customizable Sea Water Reverse Osmosis systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.

-

Max. feed water temperature: 42°C

-

Equipment upgrade for TDS up to 50,000 ppm

-

H2S, turbidity and organics must be removed

-

Feed water TDS: 10,000-42,000 ppm

-

Operating pressure: 700 to 1,000 psi

-

pH tolerance range: 3-11

-

Feed water pressure: 40 to 80 psi

-

Antiscalant dosing is required

-

Max. Iron content: 0.05 ppm

-

Powder coated steel frame

-

Heavy duty 5 micron cartridge prefilter

-

Sea water resistant SS pump

-

Microprocessor/PLC based control panel & VFD

-

Glycerin-filled 316 SS prefilter pressure gauges

-

Product & reject flow meters

-

TFC spiral wound membranes

-

FRP membrane housings

-

460V/3Ph/60Hz power supply

-

Low & high pressure switches

-

Permeate TDS monitor

-

Stainless steel high pressure piping

-

Stainless steel throttling valve for reject stream

-

Automatic feed shut off valve

-

Energy recovery on 64K GPD and larger

-

Booster pump

-

380-415V/3Ph/50Hz power supply

-

Product tank level switch

-

pH controller with sensor

-

ORP controller with sensor

-

Hour meter

-

Cleaning skid

-

50 micron bag filter for open intake

-

Carbon prefilter

-

Multimedia prefilter

-

UV sterilizer

-

Custom designed units

-

Export crating

-

Chemical dosing units