Eco-Dec - Model Ex 150 Wx -Industrial Solvent Regenerator/Recycler System

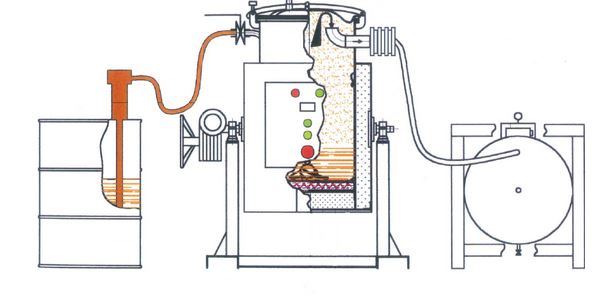

Currently, 4 different capacities of solvent regenerators are manufactured in series: Capacity: 150 litres. Installed Power: 6 kW. Supply Voltage: 3x400V+N. Dimension HxLxl (mm): 1500x1000x1000. Mass: 300 kg. Cycle Time: 4 hours.

A wide range of solvent regenerators that are suitable for recycling all types of solvents, allowing the recovery of residues, which are available in liquid or solid form in the bottom of the regenerator at the end of the recycling cycle.

The process makes it possible to recover 99.9% of the solvent, which is perfectly pure and ready to be reused.

These systems solve the problems of cost, storage and disposal of the solvents used, and drastically reduce the need to purchase new solvents.

We offer a 10-year warranty on the centrepiece of our solvent regenerators: the aluminium alloy heating plate.

The capacities of the EX20 / EX50 / EX150 / EX500 regenerators range from 20 to 500 litres, for a recycling rate of 100 to 2500 litres per day.

Standard regenerators are equipped with:

- A tilting mechanism

- A residue outlet at the back

- Temperature and level probes

- A control box

- The solvent used is poured into the stainless steel tank of the regenerator.

- It is then heated by the Aluminium heating plate.

- When the solvent reaches its boiling point, it goes into the vapour phase, which is naturally collected in the condenser.

- The pure solvent vapour is cooled via a water condenser system allowing optimal heat exchange.

- A 100% pure solvent is harvested and ready to use.

- The residue, also called a contaminant, is recovered in the regenerator tank, either manually or automatically.

- Our unique patented bottom heating system has the following advantages:

- Almost no maintenance

- Very high efficiency

- Quick and easy cleaning

- Significant energy savings

The vacuum system allows the operating temperature to be reduced.