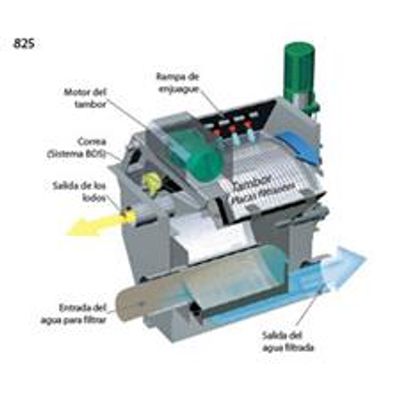

INNOVAQUA - Drum Filter

The operative cycle is simple: the fluid to be filtered enters into a rotating drum. The periphery of the drum is made of solid stainless steel perforated plates. Impurities larger than the holes are trapped on the inside of the filter plates. The drum rotates slowly (3 - 8rpm, depending on model) dragging the impurities out of water. A ramp located flush at the top of the drum, then cleans the plates to evacuate the impurities in the output channel of the sludge. The filters are designed to withstand any corrosion, as they have been built in stainless steel 304L or 316L stainless steel for salt water applications. Requires little maintenance. Constructed entirely of stainless steel, can be installed quickly thanks to a unique mounting system.

Filters are available from 25um to 120um and with water flow from 30 m3 / h to 2,700 m3 / h.

As options, filters can be equipped with:

- Main control Panel. Electrical control box with selector MANUAL/STOP/AUTOMATIC, made of polyester reinforced with fiberglass IP65.

- Backwash pump. Vertical Pump 304L or 316L stainless steel. The pump is supplied with all fittings in PVC.

- Water level probe. A level sensor detects and controls the filter mesh (variation of water level in the filter) and sends a signal to the relay timed level, located in a control cabinet, which enables the implementation of the pump and drum rotation for a few seconds.