Devise - Model Ultra-Clear -Innovative Package MBR Wastewater Treatment Plant

The ULTRA-CLEAR Bio Plants incorporate the most up to date wastewater treatment technology, namely that of submerged Membrane Biological Reactor (MBR). These “Package Bio Plants” offer a smart solution that surpasses other conventional ones of similar capacities, both in terms of compactness and performance. These units are completely autonomous and provide high level of treatment, combining Biological Treatment + Ultrafiltration (UF) + Disinfection. They are produced in compact units of ISO-container dimensions for easy shipment & installation and are suitable for decentralized treatment facilities with high effluent requirements. The ULTRA-CLEAR systems for the small packaged plants (i.e. up to 200 m3/d), incorporate flat sheet UF membranes of high packing density and for packaged units with capacities ranging from 300 up to 5,000 m3/d they incorporate reinforced hollow fiber UF membranes.

The ULTRA-CLEARTM BioPlants incorporate the most up to date wastewater treatment technology, namely that of submerged Membrane Biological Reactor (MBR). These “Package Bio Plants” offer a smart solution that surpasses other conventional ones of similar capacities, both in terms of compactness and performance.

These units are completely autonomous and provide high level of treatment, combining Biological Treatment + Ultrafiltration (UF) + Disinfection. They are produced in compact units of ISO-container dimensions for easy shipment & installation and are suitable for decentralized treatment facilities with high effluent requirements.

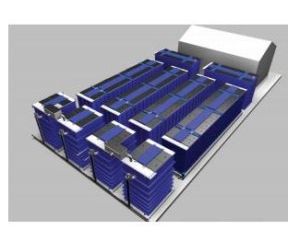

The DEVISE ULTRA-CLEAR™ BioPlant design philosophy can also be used for bigger capacity installations where the biological reactors can be built locally either in concrete or modular steel. The Membrane Operating System (membrane cell & machine room) is of packaged form, thus offering all the benefits of a smart prefabricated solution.

The ULTRA-CLEAR™ systems for the small packaged plants (i.e. up to 200 m3/d), incorporate flat sheet UF membranes of high packing density and for packaged units with capacities ranging from 300 up to 5,000 m3/d they incorporate reinforced hollow fiber UF membranes

The ULTRA-CLEAR™ Units are exceptionally compact and can be dispatched to any location around the world, virtually ready to "plug & play". DEVISE designs these Bio Plants so as to cater for all environments either being extreme hot or very cold.

These plants are engineered to the highest specifications and incorporate all necessary features for an automatic operation, providing optimum performance at the lowest possible maintenance.

The membrane modules are supplied by first class manufacturers with proven performance and worldwide service.

The modules are designed and operated as to produce high flux rates without suffering from rapid fouling growth, consequently providing a reliable long life operation.

The DEVISE ULTRA-CLEAR BioPlants can treat Municipal Sewage as well as Industrial Wastewater offering effluent quality as shown in the following table:

ULTRA-CLEAR BioPlant Effluent Quality

- BOD5 < 5 mg/L

- COD < 50 mg/L

- TSS < 3 mg/L

- TKN < 10 mg/L (with denitrification)

- Turbidity < 1 NTU

- Total Coliforms ≤ 100 CFU/100 mL (without residual disinfection)

- Virus rejection 3log

Smart Design

- Integrated tertiary treatment

- Fully tested before dispatch

- Ready to plug & play

- Modular design

- Space saving – Small footprint

- Quick installation and start-up

- High effluent quality suitable for reuse

Easy & Reliable Operation

- Fully automatic

- Controlled by PLC

- User friendly interface (touch screen HMI)

- Remote monitoring

- Excellent performance with process stability

- First-class membrane material

- High quality & consistent permeate production

- Easy & low maintenance

The DEVISE ULTRA-CLEAR Bio Plant design philosophy can also be used for bigger capacity installations where the biological reactors can be built locally either in concrete or modular steel. The Membrane Operating System (membrane cell & machine room) is of packaged form, thus offering all the benefits of a smart prefabricated solution.

Prefabricated Membrane Filtration Tank (MFT)

The Membrane Filtration Tank (MFT) is a pre-engineered packaged treatment system that incorporates all necessary process steps within a box-like structure. The box is made in mild steel with specific heavy-duty anticorrosion protection and has the dimensions of an ISO-standard container. Due to its design, the prefabricated MFT can be readily transported from site to site by means of a trailer truck and is suitable for aboveground installation. The operation of the containerized MFT is as simple and user-friendly as possible and the same applies for its maintenance requirements.

Membrane Modules

For all its applications DEVISE uses modules that are supplied by world-leading membrane developers, manufacturers and suppliers with numerous references in the field of municipal and industrial wastewater treatment using the iMBR technology.

Containerized Machine Room

The majority of the equipment necessary for the operation of the MFT is installed inside a containerized machine room which is a specially modified ISO standard container that comes complete with lockable doors, lighting, internal wiring and ventilation.

The standard models of the packaged plants are designed and constructed in two main types, namely the Portable MBR Series [P-MBR] consisting of easily deployable containerized units, and the Modular MBR Series [M-MBR] consisting of a combination of “site-erected” tanks and prefabricated units with a view to provide a Packaged Solution that offers a quick and cost effective project implementation. The standard designs and models for the Municipal Sewage Treatment Plants are indicated below for the two main MBR Series.

Portable Type [P-MBR]/Model Max. Capacity (m3/day)

- P-MBR/100 100

- P-MBR/150 150

- P-MBR/200 200

- P-MBR/300 300

- P-MBR/500 500

- P-MBR/750 750

- P-MBR/1000 1000

Modular Type [M-MBR]

- Models Max. Capacity (m3/day)

- M-MBR/500 500

- M-MBR/750 750

- M-MBR/1000 1000

- M-MBR/1250 1250

- M-MBR/1500 1500

- M-MBR/2000 2000

- M-MBR/2500 2500

- M-MBR/3000 3000

- M-MBR/3500 3500

- M-MBR/4000 4000

- M-MBR/4500 4500

- M-MBR/5000 5000