Interceptor - Model 3115 HRD 8L-20L-50L -Explosion Suppression System

The Interceptor-HRD explosion suppression system is designed to provide an active method to protect process equipment from a dust explosion hazard. The principle of operation for the Interceptor-HRD system is timely detection of the pressure rise during the initial stage of an explosion, followed by fast injection of an extinguishing agent.

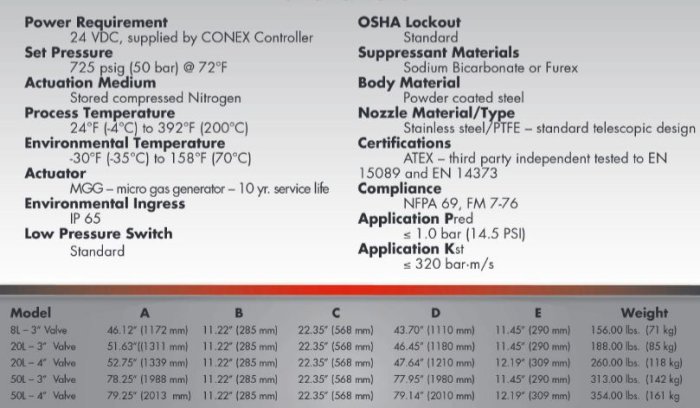

The 8L/20L/50L Interceptor-HRD bottles include a low pressure monitoring switch, OSHA lockout and a telescopic nozzle as standard features. Each HRD suppression bottle is actuated by a micro gas generator (MGG) that reduces maintenance costs with a 10 year service life. Several suppressant agents are offered to cover both sanitary and non-sanitary applications. The 8L/20L/50L bottles can come equipped with a 90° elbow transition or a straight transition. The Interceptor-HRD suppression bottles can be used for isolation purposes as well. Chemical isolation is often used in conjunction with explosion suppression, explosion venting, or flameless venting.

Chemical suppression and isolation systems are designed for use in almost any process handling combustible dust. The Interceptor-HRD system can be used for pneumatic conveying systems, dust collection systems, cyclones, mills, dryers, conveyors, and storage vessels.