Ozone Robot - Ion Exchange-Integrated Device

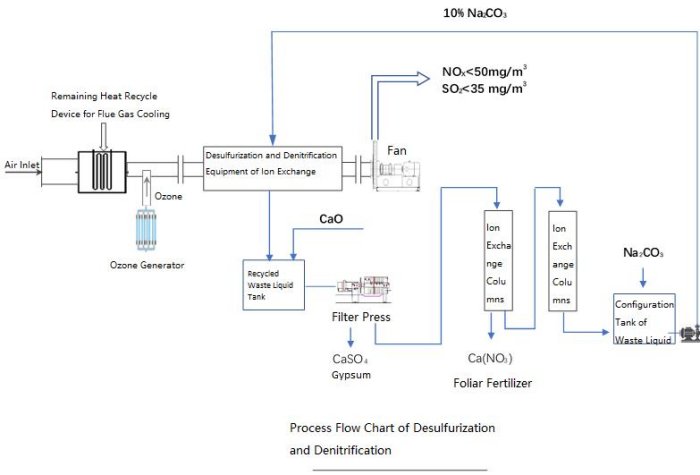

The ion exchange-integrated device can produce simultaneous desulfurization and denitrification of flue gas.

The core patented product - "TRS New Type Ion Exchange Material" is used for new technology and a new process of integrated co-processing of desulfurization and denitrification. This achieves low-concentration emission of sulfur dioxide and nitrogen oxides in all types of flue gas.

A strong alkali ion exchange fiber is used as the core material for denitrification. After the flue gas is mixed with ozone, the NO in the flue gas is quickly oxidized to NO2 and N2O5. Both are dissolved in water and generate nitrous acid and nitric acid. Nitrates are adsorbed by the ion exchange material at the same time to achieve low NOx emission. When the ion exchange material reaches saturation, it is regenerated with 10% Na2CO3. It continues to be used after regeneration.

Regeneration of recycled waste liquid: Add appropriate amount of Ca(OH)2 to recycled waste liquid to generate CaSO4 precipitation. This is pressed into mud cake to recover gypsum and used as cement retarder. The supernatant is recovered and used to prepare the regeneration solution. The generated Ca(NO3)2 is used as a "foliar fertilizer" or soil amendment.

The ion exchange absorption system mainly includes ion exchange columns, ion exchange fibers, water pumps and induced draft fans.

Under the same absorption rate, the normal operation resistance of this system is only 1000-1200Pa, and the energy saving effect is obvious.

- The integrated co-processing of desulfurization, denitrification and acid gas removal can achieve ultra-low emissions of pollutants

- No yellow or white smoke are generated

- Almost no waste water and solid waste are produced, and the by-products of desulfurization and denitrification can be fully utilized as resources

- Low operating cost