Jiangsu Yianteng

- Home

- Companies

- Jiangsu Yianteng

- Products

- Iridium - Model MMO Series - Titanium ...

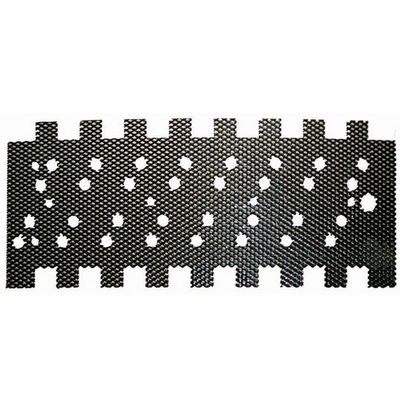

Iridium - Model MMO Series -Titanium Anode

FromJiangsu Yianteng

Application areas: Metal foil, Electrolytic copper foil, Galvanized steel plate, Cathodic protection, Organic electrolytic synthesis, Chromium plating, Etching solution regeneration and Non-ferrous metal recovery, Cyclone electrolysis, Hydrometallurgy, HHO generator, Sewage treatment and other industries.

Most popular related searches

non-ferrous metal recycling

ferrous metal recovery

non-ferrous metal

fluoride ion content

metal recovery

cathodic protection

sewage treatment

sewage treatment industrial

sewage treatment industry

sewage

- New type MMO anode and Lead Dioxide(PbO2) coated Titanium Anode for Electrowinning of Copper, Nickel, Cobalt;

- The electrode usSubstrate: Titanium (Gr1、Gr2)

- Coating oxide: IrO2+Ta2O5+X

- Current density: <15000A/M2

- Precious metal content: ≥20g/m2

- Sulfuric acid concentration: <60%

- Temperature: <80℃

- Fluoride ion content: <50mg/L

- Ph value: 1-12e titanium mesh as substrate, and coated with Mixed Metal Oxide(MMO, no Iridium) or Lead Dioxide(PbO2);

- Comparing with lead alloy anode, our anode have advantages as following:

- 1, High purity of cathode copper or other products.

- 2, Lower power consumption.

- 3, Endure high concentration of chloride, fluoride ions...

- 4, Longer service lifetime than lead anode.

- 5, No Anode sludge produced.

- 6, No secondary pollution to the cathode copper or other products.

- 7, Light weight, save labor cost.

- The substrate is mainly made of industrial pure titanium, which can be processed into any shape and size with high accuracy, and is dimensionally stable during use. This can ensure that the electrode equipment can work stably under a constant voltage for a long time, and can also guarantee the high purity of the product.

- The oxygen evolution potential is low, and the energy saving effect is obvious compared with the traditional anode, and the life is long.

- After the active layer is deactivated, it can be recoated and the substrate can be reused.

- This kind of electrode products of Yian Teng company are specially designed according to the actual operating conditions of each electrode to ensure that the best working effect can be achieved in any medium or application.