- Home

- Companies

- Iron Creek Group LLC

- Products

- Iron-Creek - Model M1 - Infrared ...

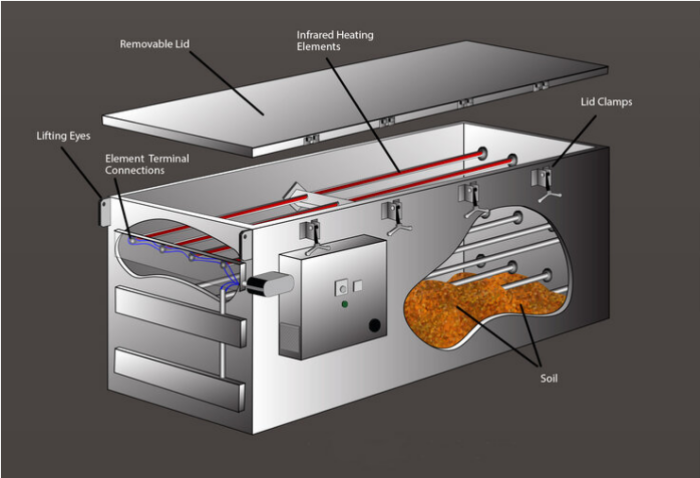

Iron-Creek - Model M1 -Infrared Thermal Conduction Technology

- Able to treat soils and sludges within 24 to 72 hours per batch

- Infrared Thermal is a simple design - works via vapor pressures

- Has no moving parts, does not require blowers or exhaust fans

- Currently in operation in Antarctica with the U.S. National Science Foundation

Our clients depend on our team to deliver complete remediation of all organic contaminants, safely, on time, and on budget.

Treating Contaminants from the Arctic Circle to Antarctica

Reclaim land with explosives-impacted soil. Our Enhanced Thermal Conduction technology safely restores soil, allowing cities and states to safely rebuild. Pictured is a photo from the notable Ravenna Army Ammunition Plant in Ohio where artillery was made for WWII, the Korean and Vietnam War.

Restoring Antarctica`s Soil

Our technology meets the most stringent environmental regulations on the planet, taking our team to Antarctica to restore impacted soil in challenging conditions.

Soil Restoration Edson Pipeline

11,000 tons of hydrocarbon impacted soil in Edson, Alberta was restored in approximately 6 months. Our Enhanced Thermal Conduction technology utilizes petroleum-impacted soil to fuel the restoration treatment.

70-Year Old Hydrocarbon Contaminants

The remediation of this heavily impacted hydrocarbon dump site in Yukon’s City of Whitehorse took 11-months to fully restore.

- Safe, predictable & cost-effective.

- Proven methodologies to delist waste, reducing paperwork.

- On-site treatment eliminates the liability associated with transporting hazardous waste.

- Our patented systems are mobile, fitting into the cargo area of small planes, allowing for the restoration of contaminated soil and sediment in the most pristine places on Earth, like Antarctica and the Arctic Circle.

- Treated soil can be safely seeded and revegetated to facilitate surface reclamation, sustainable plant growth and equivalent land capability.

- There is no requirement for soil pre-treatment or screening.

- Our process is 100% waste free. There is no reject material from treatment.

- We work within the confines of the site and are proficient at adapting to meet the needs and regulations of the location.