International Surface Technologies (IST)

- Home

- Companies

- International Surface Technologies ...

- Products

- ISTpure - Model CSR 60v - Continuous ...

ISTpure - Model CSR 60v -Continuous Solvent Recycler

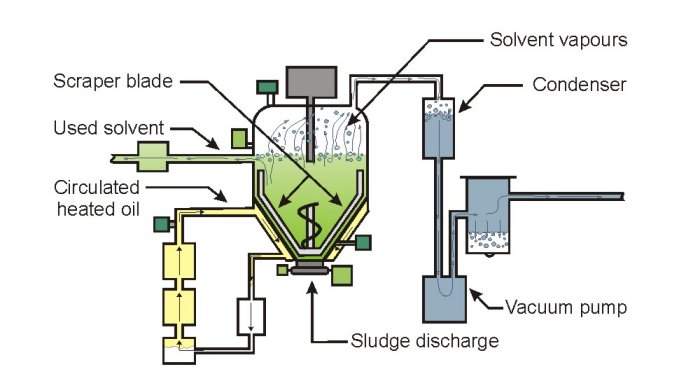

This continuous solvent recycler is an evaporative distillation process unit. The waste solvent automatically enters the distillation vessel utilizing the standard vacuum pump provided with the solvent recovery still.

Most popular related searches

continuous solvent recycling

solvent recycling

solvent waste

dirty solvent

evaporator distillation

waste recycling

toxic waste

vacuum pump

cleaning solvent

sludge heating

The heated thermal oil recirculates in the distillation vessel jacket. The solvent sludge is heated to a programmed temperature to create vapour. The solvent vapour exits the boiler and travels through a condenser.

Clean, condensed solvent exits to a storage vessel ready for reuse. This entire process is controlled by a PLC.

We always evaluate your solvents and contaminants MSDS sheets prior to recommending the proper system. It is very important to also identify the possible presence of nitrocellulose and acids in your dirty solvent mix.

- General manufacturing

- Aerospace and aviation

- Automotive

- Marine

- Petroleum

- Flexography

- Lithography

- Wood finishing

- Power & energy

- Pharmaceutical

The product features that distinguish the ISTpure line of solvent recyclers :

- Recovery rate : 99.5% and more.

- Virtually maintenance free.

- Recycle time : 4 to 6 hours.

- Eliminates 90 % of toxic waste.

- Recycles most popular solvents, including mineral spirit, flexo & litho solvents.

- Return on investment : less than one year and Kw consumption less than 2 cents per gallon.

- Safety standards : Class 1, Div. 1, Group D.