International Surface Technologies (IST)

- Home

- Companies

- International Surface Technologies ...

- Products

- ISTpure - Model SRC Series - Continuous ...

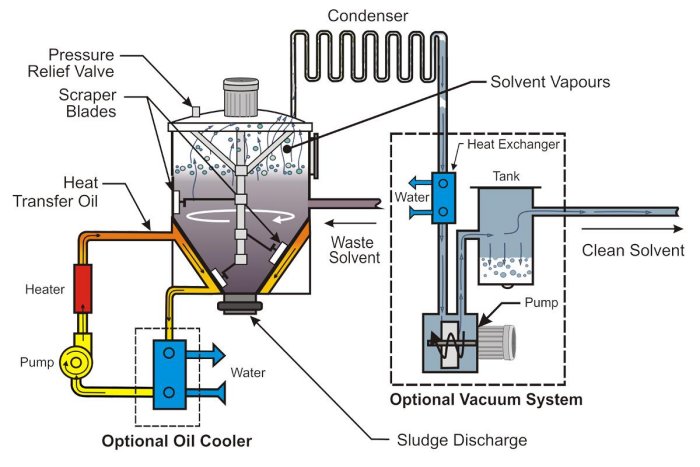

ISTpure - Model SRC Series -Continuous Flow Solvent Recycling Systems With Scraper

SRC Series Solvent Recyclers allow used solvent recycling in continuous-flow evaporative distillation process. Units available in tank capacities of 30, 60, 120, 180 and 240 liters and deliver production yield of up to 375 liters per hour. Waste solvent automatically enters distillation vessel using standard vacuum pump provided with solvent recovery still. Heated thermal oil recirculates in distillation vessel jacket. Solvent sludge is heated to programed temperature to create vapor which exits boiler and travels through condenser. Scraper rotates at bottom of distillation vessel to keep it clean and avoid calcination of chemicals. Entire process is controlled by PLC. Clean, condensed solvent exits to storage vessel ready for reuse.

Most popular related searches

solvent recycling

continuous solvent recycling

solvent recycling system

recycling system

cleaning solvent

digital temperature controller

process automation

solvent waste

sludge discharge

dirty solvent

- Recovery rate: 99.5% and more.

- Virtually maintenance free.

- Recycle time: 4 to 6 hours.

- Eliminates 90 % of toxic waste.

- Recycles most popular solvents, including mineral spirit, flexo & litho solvents.

- Return on investment: less than one year and Kw consumption less than 2 cents per gallon.

- Safety standards: Class 1, Div. 1, Group D.

- Durable: Built with robust, corrosion-free 304 and 316 stainless-steel construction.

- Safety: Highest level of safety C1D1 certified and Class I | Div | Group D Explosion Proof.

- Tank sizes: Available in 60, 120, 210, 680, 1,515, and 1,890+ liters sizes.

- Effective: Recover up to 95% of available solvent from the waste mix.

- Fully Automated Process: Everything is automated, from filling of clean solvent, to discharge of sludge, to temperature control in between.

- Assisted by PLC: Operate on a fully automated process assisted by a touchscreen PLC with predetermined parameter settings and built-in alarm signals.

- Touchscreen Allen Bradley PLC

- Safety Features and Temperature Controls

- Class I | Div | Group D Explosion Proof

- Automatic filling

- Automatic clean solvent discharge

- Automatic waste sludge discharge

- Anti-spill sensors

- Remote Ethernet or wifi PLC access

- Two (2) sight glasses

- Electric heating thermal oil jacket

- Dual automatic filling

- Dual container collection

- Oil cooling

- Purge box

- Intrinsically safe tablet computer

- Cellular access PLC

- Explosion-proof lighting

- Liquid ring vacuum assistance

- Nitrocellulose safety features

- Internal scraper

- Water / Solvent separator

- Maintenance platform

- Automatic sludge pump out

- Fractionation tower

- 25% + Energy savings package